For use as an RDF rather than for hazardous waste incineration

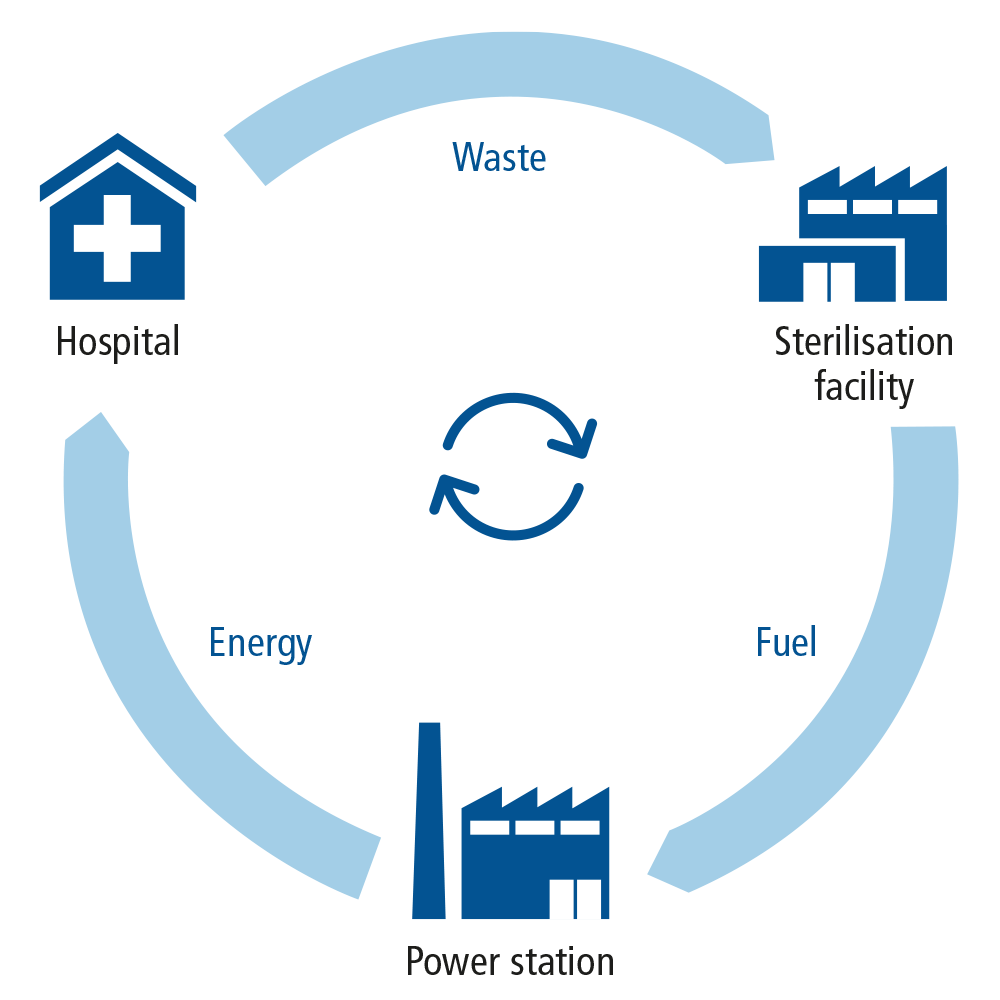

The goal is massive and requires many different smart steps: to create a circular economy. REMONDIS took up this challenge many years ago and has continuously been improving raw material recovery rates and doing everything in its power to make sure its various recycling processes have an efficient energy footprint. This is also true for its incineration activities. REMONDIS Medison has now developed a revolutionary method for incinerating highly infectious hospital waste. Thanks to REKOMED, substances that would previously have to be sent to hazardous waste incineration plants can now be transformed into refuse-derived fuel. This can then be used to generate energy in conventional recycling plants.

Highly effective against the Ebola, coronavirus and HIV viruses

To achieve this, infectious and highly infectious residual substances are cleansed to such an extent that they no longer fall into the ‘hazardous waste’ category. This highly effective sterilisation process is performed at Lünen using a vacuum steam system that has been approved by the Robert Koch Institute and is even effective against Ebola, coronavirus and HIV viruses. At the end of the process, the now harmless material can be sent straight to the recycling facility at the Lippe Plant to produce electricity and steam.

Thanks to this procedure, around 5,400 tonnes of hospital waste are currently being used to produce sufficient electricity for around 4,000 4-person households every year. Ulrich Hankeln, managing director of REMONDIS Medison, stressed: “Our REKOMED system is an attractive offering for hospitals and for a large part of their highly infectious waste. Besides having their refuse handled in line with all rules and regulations and receiving all waste management documents, they are also provided with an additional tool at standard market conditions that supplies energy and improves their sustainability footprint.”

State-of-the-art technology packed up safely. The whole facility has been designed so that the material remains in a fully enclosed system from the moment the bins are handed over all the way through to the final sterilisation stage

“Our REKOMED system is an attractive offering for hospitals and for a large part of their highly infectious waste.”

Ulrich Hankeln, Managing Director of REMONDIS Medison

Safely packed in the sealed bins, the material is fed into the plant where both the bins and their contents are cut up

A safe system, a positive energy footprint

The sterilisation procedure and the transformation of the materials from hazardous to harmless takes place in a fully automated enclosed system using a vacuum steam sterilisation process: the bins collected from the hospitals and their waste contents are first cut up in the enclosed system. A screw conveyor then transports the cut up material into the two process tubes. The next step is to remove all the air from the tube so that the actual sterilisation procedure can begin. The material in the process tube is heated up with direct steam.

With the hot steam reaching a temperature of 138°C, it is able to kill off the infectious bacteria, germs, viruses and spores. Sterilised in this way, the material can be sent for full thermal treatment. At no stage do the staff come into contact with the material. The system is fully encapsulated and the two units can each handle 500kg per hour. The actual process takes around sixty minutes. Using this system improves the hospitals’ carbon footprint. Which is why Ulrich Hankeln underlined REKOMED’s growth potential and its competitive advantage: “Our offering can be used across the whole of the country. We believe that demand will grow as the subject of sustainability becomes ever more important for hospitals – a development that is, in particular, being driven by the owners.”

Turning infectious waste into climate-friendly energy

The REKOMED process is a perfect solution for hospitals that are looking for sustainable ways to manage their waste

Image credits: image 1–3: © REMONDIS