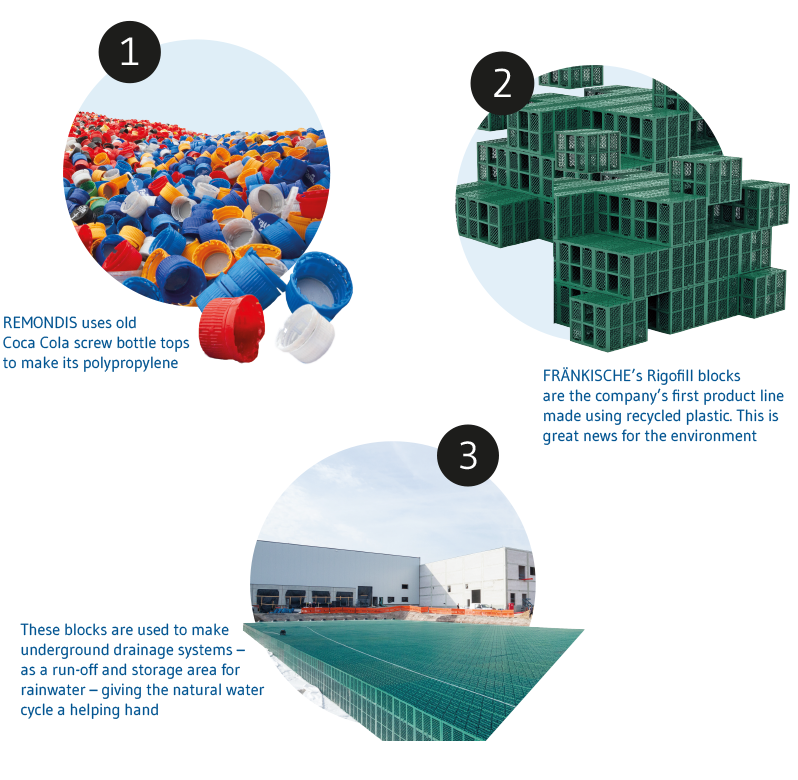

A collaborative and sustainable project

Coca-Cola European Partners Deutschland GmbH (CCEP), FRÄNKISCHE and REMONDIS have come up with a truly sustainable project for managing rainwater – a project that also helps protect the environment. First, the recycling experts REMONDIS transform CCEP’s used bottle tops into high quality recycled plastic, which FRÄNKISCHE, a leading manufacturer of pipe systems, then uses to produce so-called Rigofill blocks. These blocks are used to make underground drainage systems – as a run-off and storage area for rainwater – giving the natural water cycle a helping hand in areas where humans have sealed off the surface. The Rigofill storage modules are not only of an excellent quality, they are also particularly environmentally friendly: FRÄNKISCHE manufactures them using top quality recycled plastic rather than virgin plastic.

High quality recycled plastic

No matter what the product, FRÄNKISCHE only ever uses quality-assured materials in its production processes. Its material of choice for its Rigofill blocks is PLANOPROP, a brand-name polypropylene product made by REMONDIS that has received a number of awards. Every year, over 2,700 tonnes of CO2 are saved producing this recycled plastic compared to the production of virgin plastic. What’s more, the recycled material more than meets the company’s high quality requirements.

To be able to produce these recycled plastic pellets, REMONDIS first sorts, cuts up and washes CCEP’s bottle tops before recycling them. It is essential that they are sorted and screened well to ensure that the plastic does not lose its material properties. PLANOPROP is particularly suitable for manufacturing products that need to be lightweight, stable and long-lasting. Being such a robust material, PP is perfect for the Rigofill system and meets the strict requirements of underground civil engineering work. When installed correctly, these storage blocks can last for many years. And, once the Rigofill block does finally come to the end of its useful life, the plastic can be recycled again – further underlining its green credentials. Conserving natural resources, recovering raw materials from products, keeping transport routes as short as possible and reducing carbon emissions – this is what sustainable industry must look like to safeguard the future.

Rainwater management with Rigofill

For over 20 years now, the pipe specialist FRÄNKISCHE has been developing and manufacturing a whole range of products and systems to manage rainwater. These products recreate the natural water cycle wherever it has been cut off. Huge swathes of land in developed countries are being covered in manmade structures. Surfaces are being sealed off by roads, squares and residential areas – not to mention industrial and trading estates – all of which prevent rainwater from being absorbed into the ground.

And if the rain can’t seep into the ground, it will take another route. The results: flooded towns and falling groundwater levels, damaged infrastructure and buildings. The Rigofill system is used to prevent this happening: being a modular system, the blocks can be combined to create as big or as small a structure as needed. Once installed they form a drain that can temporarily store the pre-treated rainwater before gradually releasing it again. As the blocks are placed underground, they have to be particularly robust and able to withstand pressure caused by earth movement, traffic or indeed groundwater. This is where the composition of the material used to make the Rigofill system plays such an important role. The Rigofill blocks are particularly strong, with the different types designed to fulfil a variety of requirements – from heavy traffic to quieter surfaces. All of the FRÄNKISCHE blocks have been made to last for at least 50 years.

The innovative material life cycle

Image credits: images 1–4: © REMONDIS