Improving the energy consumption of industrial facilities

XERVON is expanding possibilities for optimising energy use by industrial plants by means of energy audits based on the TIPCHECK standard. One particular plus factor is at the same time data and facts relating to financial aspects. These reveal in very precise terms what the company can save, demonstrating how quickly investment in a more efficient insulation can pay for itself.

Insulation has great potential

Companies have been turning their attention to energy efficiency for some time now. Nevertheless, there is still a vast potential for savings – especially with regard to the insulation of plant and equipment, which in many cases has not been upgraded for decades. At the same time, it is worthwhile doing something especially in this area. According to studies, better industrial insulation could save 620 peta joule per year in Germany – as much energy as is used by ten thousand households. With respect to climate protection, 49 megatons of CO2 could be avoided – a scale comparable to the exhaust produced by eight million cars.

49 mega tonnes of CO2, could be saved in Germany every year through better insulation in the industrial sector.

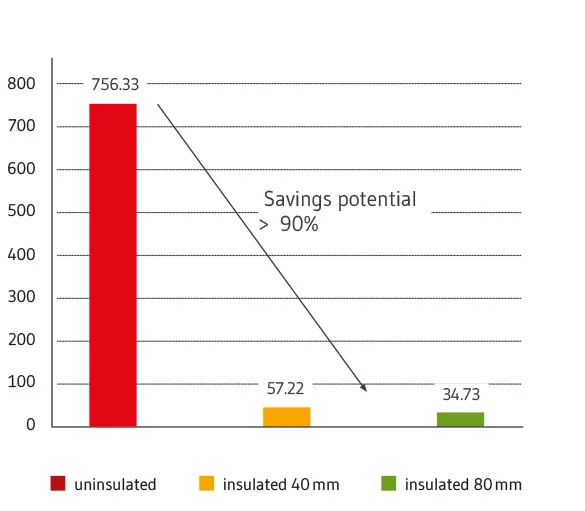

Energy savings of over 90 per cent possible

In its capacity as specialist in industrial insulation, XERVON develops sophisticated solutions to minimise losses of heat, which makes it possible for business enterprises to reduce their total plant costs in a sustainable manner. In the case of insulation systems that are not yet designed to maximise energy efficiency, an energy-savings potential of up to 90 per cent can be achieved with XERVON. The significant cost savings that are linked to this ensure that such investments will pay for themselves in a brief period of time, frequently even in the space of a few months.

Energy audit clears the air

In addition to advice, conception and installation, XERVON has also been performing energy audits based on the TIPCHECK standard since the beginning of February 2018. Specially trained, certified staff members determine the exact weak points and energy leakages in the technical insulation systems. The latest in thermal imaging technology is used to identify heat leaks. In combination with drones, XERVON uses thermography even for inaccessible areas, for example the roofs of tank systems.

As a result of the considerable savings, investment in 40 mm insulation pays for itself within a period of 3 months.

In addition to the analysis, the savings potential to be expected is estimated in the TIPCHECK energy audit and suggestions for action that can be implemented immediately are developed. This also includes concrete calculations of the energy and cost savings that can be realised as well as the individual period of amortisation for the investment. From the perspective of the industry, these data and facts offer a reliable foundation for decision-making. Around 75 per cent of companies that have had the audit performed are already using its recommendations or are planning to do so in the near future, for instance the next time there is a system shutdown.

A partner in implementation

In implementation, XERVON offers all services from one source. The most economical insulation thicknesses are selected on the basis of the insulation concept and specified in terms of the respective requirements. The enterprise produces the components required in its own workshops or directly at the site and includes the installation. In some situations, optimisation of insulation at industrial plants also receives financial support: The Federal Office of Economics and Export Controls (Bundesamt für Wirtschaft und Ausfuhrkontrolle – BAFA) supports measures aimed at boosting energy efficiency by means of highly efficient thermal and cold insulation with subsidies amount to up to EUR 150,000.

Inefficient insulation not only causes energy to be lost. It also reduces the efficiency levels of the plant, increasing the temperature drop on lines, accelerating the cooling of warehouse containers and reducing the efficiency of the plant as a whole.

Example from the field of practice: Advantages that speak for themselves

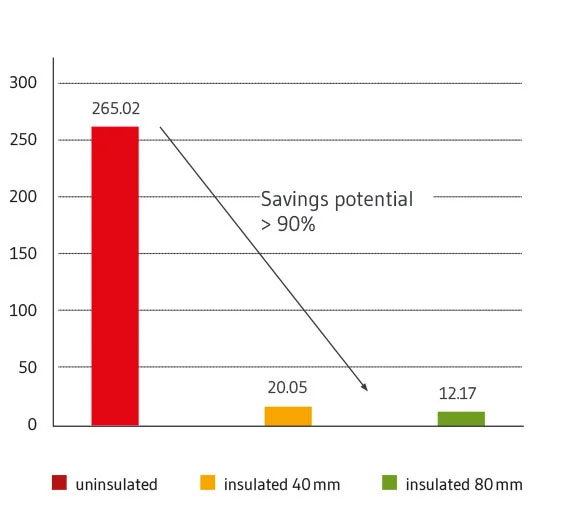

A chemicals company introduces a medium at a temperature of 100 degrees Celsius into a pipeline with a nominal width of DN 150. The average mean annual atmospheric temperature according to weather data at the site is 11.2 degrees C. at a wind speed of 1.00 m/s. With these parameters, efficient insulation reduces heat-loss costs to the company by more than 90 per cent (diagram 2). With a DIN 150 pipeline, cost are reduced from EUR 265 per meter and year to EUR 20 or 12, depending on the thickness of the layer of insulation. Investment in better insulation thus pays for itself in a period of a few months. It is difficult to find a more profitable investment.

Loss of heat per metre of pipe (h/m)

Loss of heat per metre of pipe in Euros

Savings potential for insulated pipes in Euros per meter

TIPCHECK – Technical Insulation Performance Check

The TIPCHECK audit, which is specialised in technical insulation systems, corresponds to energy audit standards EN 16247 and ISO 50002. It was developed by the European Industrial Insulation Foundation (Eiif). The primary objective of the non-profit Eiif is to reduce CO2 emissions of industrial plants and systems by means of sustainable insulation.