Online systems open up new opportunities

For years now, XERVON Instandhaltung has been offering condition monitoring – a process that involves monitoring machine elements (for example using vibration analyses) and documenting their condition. By doing so, they can identify individual machine parts that are broken or suffering from wear and tear and so prevent plant outages. The experts have now gone a step further. By integrating the recorded measurements into online systems, customers now have access to a range of features enabling them to use this data even more productively.

New services benefit the customers

Condition monitoring is one of XERVON Instandhaltung’s core areas of expertise – and there is a good reason for this. At the end of the day, measuring and analysing such data is an effective way to minimise plant downtime, prevent unexpected production outages and increase a facility’s operational life. What’s more, individual machine parts can be used for as long as possible as their condition is being permanently monitored.

Condition monitoring reduces the chances of an unexpected production outage to an absolute minimum.

Digitising this information and integrating it into online systems open up even more advantages – and this is something that XERVON is making the very most of to offer their customers even more benefits. Steven Brenner from XERVON’s condition monitoring division explained: “The different ways the data can be used, once it is has been entered into an online system, are pretty much boundless. Our customers tell us exactly what they want and we set it up.”

Network solutions create best practices

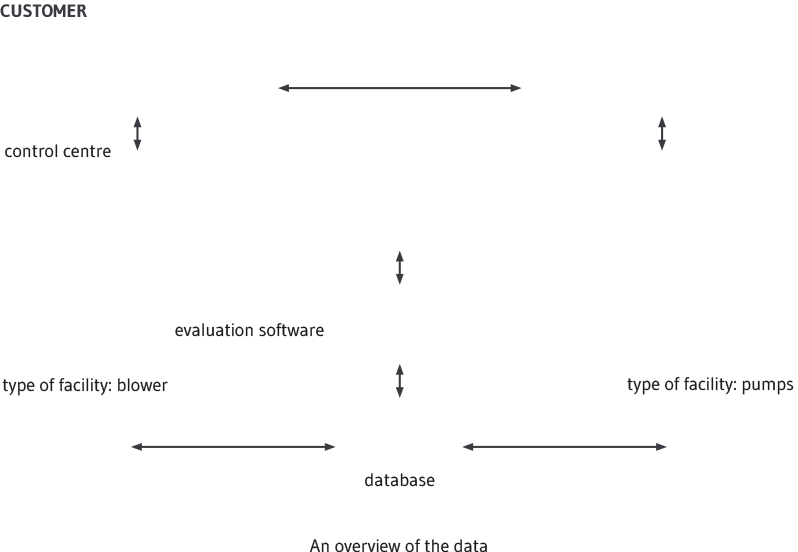

One particularly useful feature of such online systems is that they enable data from all company plants to be recorded and evaluated centrally so that best practices can be implemented across all similar facilities. One example: a manufacturer uses condition monitoring systems to monitor its various process plants around the world. All of the information and data recorded are transmitted online to a central database and then analysed. Feedback, recommendations and improvement measures can then be sent back to the individual plants via the digital network.

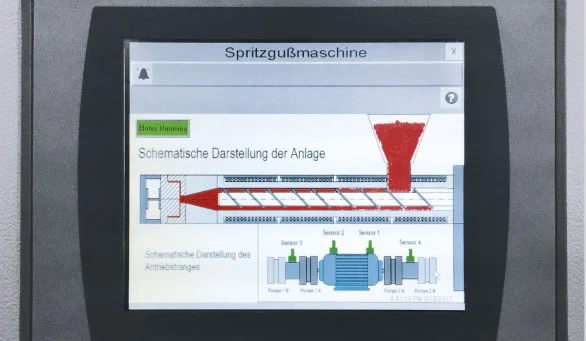

The online system’s panel on the CM box; the data from the individual sensors can be viewed here

Adding the data to other systems

An online system, which XERVON is currently setting up at a large German automobile supplier, illustrates perfectly just what is possible when digital support is available. One of the main goals here is to integrate the maintenance-specific data into the customer’s other systems, such as its maintenance planning and control systems (IPS). This involves interpreting the recorded production data and plant parameters, further processing this information and then making it available for the higher level planning systems.

XERVON Instandhaltung‘s condition monitoring experts have access to a directory containing data recorded from monitoring over 8,000 machines.

This bespoke system has been designed so that it is not only possible to record the data but also to enable it to be trans-mitted, forwarded, stored and processed in a variety of ways. If alterations need to be made to the system, such as changing the measurement tasks, then this can be done via remote access – a solution that is quick and can be carried out no matter where the person may be.

Automated measurements – just in time

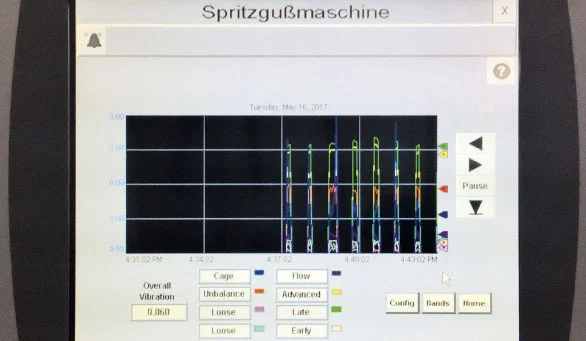

XERVON Instandhaltung has also been monitoring sections of a production plant for a plastics processing business. Meaningful data can only be recorded in the ten-second gap between two production cycles. An online system has proven to be the perfect solution here as well, as it makes it possible to enter very precise settings determining exactly when the measurements should be taken. It has even been programed so that the process plant itself sends out the signal when there is a gap between cycles and again when the measurements have been taken.

Detailed analyses improve maintenance work, cut costs and increase a facility’s operational life.

Condition monitoring is already an important tool now-adays. The number of advantages it can offer, however, will continue to grow as digitisation increases. Steven Brenner concluded: “Using online systems and integrating mainten-ance data into planning and control systems will open up a whole host of new opportunities. We will be able to adapt our condition monitoring services to meet our customers’ exact requirements so that the recorded data can be used even more productively.”

The system’s recorded data

Image credits: © REMONDIS