Long-term staff retention is key for the success of the company – and this is particularly true for the technical department of a waste-to-energy plant (WtE). The current chronic skills shortage makes it difficult to recruit specialists from outside the company, for example qualified power plant operators and master power plant operators. And we don’t just need well trained staff though. Ideally the experts should know our plants as well. Which is why, two years ago, we decided to launch an in-house future leadership programme for our workforce as part of a change management process and this was a great decision. The response from our staff has been good. It’s important to us that this talent programme is not only targeted at our younger members of staff but also at our employees who have been at the company for many years and wish to gain further qualifications. Fortunately, we’ve got a good staff retention rate and the people who have been at our company for many years often say to me that there’s a good working environment here and that they don’t feel the need to change employers. That’s always good to hear. Having said that, we mustn’t ignore the fact that one-third of our workforce are baby boomers and will be retiring in the not-too-distant future. Which means we’ll be needing quite a few new leaders over the coming years. It is clear from both the way our future leadership programme has been progressing and its initial successes that we’re heading along the right path.

Michaela Schröder, managing director GMVA Gemeinschafts-Müll-Verbrennungsanlage Niederrhein GmbH

The GMVA

GMVA Gemeinschafts-Müll-Verbrennungsanlage Niederrhein GmbH is one of the largest waste-to-energy plants in Germany and operates four separate incineration lines. Each line is equipped with its own material feeder, roller-grate firing system, steam generator and complex flue gas cleaning system. Between 20 and 25 tonnes of waste are incinerated by each line every hour – the equivalent of 2,100 tonnes a day and over 700,000 tonnes a year. The energy is generated via extraction condensing turbines (50 MW and 25 MW respectively). Thanks to its WtE operations, GMVA is able to generate around 430,000 MWh of electricity and up to 150,000 MWh of district heat every year. What’s more, it also produces approx. 170,000 tonnes of bottom ash that is recycled into aggregate. In addition to this, the company operates a complex flue gas cleaning system that comprises an electrostatic precipitator, HCI and SO2 scrubbers and a fabric filter. The water needed to operate the plant is processed in an ion exchanger.

Originally in public hands, the company has been run as a public private partnership since 2001. The shareholders include the City of Oberhausen (via STOAG Stadtwerke Oberhausen GmbH), the City of Duisburg (via Wirtschaftsbetriebe Duisburg – AöR (WBD)) and the private sector firm REMONDIS.

With the skills shortage worsening and regulatory and technical requirements becoming ever more stringent, the company has turned its focus on developing strategies to drive forward the long-term retention and promotion of its qualified staff.

As WtE plants deploy highly complex systems to thermally treat waste, their staff not only need to have in-depth theoretical knowledge. They must also have extensive practical experience, gathered from both planning and implementing projects, as well as a deep understanding of all the operational processes. The company launched its Innovation Network, aka IN GMVA, to ensure these requirements will be met in the future. This initiative involves a cross-departmental group of talented and motivated employees who take on their own projects, accompanied by experienced coaches from within the company. One of the main goals of this programme is to prepare younger members of staff to cope with future challenges.

A look at the age structure within the company reveals that 49% of its 195 employees are over 50 years old. Approximately 14% of its experienced workforce will be retiring over the next seven years. This poses a risk for the business as this valuable – in many cases undocumented – knowledge could be lost to them forever. As 28% of the employees are between 26 and 40 years old, it is vital that active steps are taken now to make sure this knowledge is passed on to them.

Between 20 and 25 tonnes of waste are incinerated by each line every hour – the equivalent of 2,100 tonnes a day and over 700,000 tonnes a year.

The Innovation Network

The Innovation Network currently comprises seven participants from six different departments: maintenance, logistics, the laboratory, the mechanical workshop, technical documentation and technical project management. The group participants have, on average, been at the company for eight years and are between 25 and 39 years old. They include technicians, engineers and mechatronic engineers, with some of them having successfully completed their apprenticeships and further training courses at the business.

This future leadership programme lasts for three years. New employees are continuously given the opportunity to take part in the projects. Applications can be handed in in-house at the end of every year. Managers have also been tasked with keeping an eye out for talented staff who may be suitable for this programme. Team events are held to strengthen both the team spirit and the employees’ ties to the company.

From left to right: Lukas Brauner, Manuel Bauditz, Kim Philipp Hölzer, Timo Kraus, Joel Zganiatz, Justin-Pascal Koßmann

Innovative strength

Both the well-timed development of these employees and the implementation of their projects to increase efficiency will play a key role in the WtE plant’s performance. Having the employees take part in targeted further training measures will help continuously grow their knowledge base – something that will also reinforce the company’s innovative strength. These measures include in-house courses held by prestigious institutions covering, for example, waste management topics, project management, commercial and legal fundamentals and networking tips. Furthermore, with contacts being the be-all and end-all, the participants are encouraged to build up a network of contacts working in related industries. Getting ideas from other sectors can give new impetus and help the business to modernise its technologies and processes, in particular in the areas of automation and artificial intelligence. Looking at the processes deployed by other WtE plants can also be extremely interesting. While their core task may be the same, they often have very different technical conditions and processes. It is always exciting to look beyond one’s own business and think outside the box. The REMONDIS Group has eight waste-to-energy plants, offering us an excellent opportunity for our employees to further their skills and build up an internal network of contacts.

Recruiting apprentices via social media

The group’s first project saw them working together with a professional film team to produce a number of PR videos. These videos turn the spotlight on employees working in the different departments. Both the ideas and the script were developed together with the participants playing the main role in front of the camera. The objective here was to focus on the practical side of their work as well as to create visually modern shots, which were immediately made compatible for all popular social media platforms to reach out to and attract potential apprentices. Three-minute videos were filmed in the mechanics workshop, the electrics workshop and the logistics department. These modern and authentic videos zero in on the tasks carried out by the different departments and give a realistic impression of the working environments.

Feel free to visit the GMVA YouTube channel.

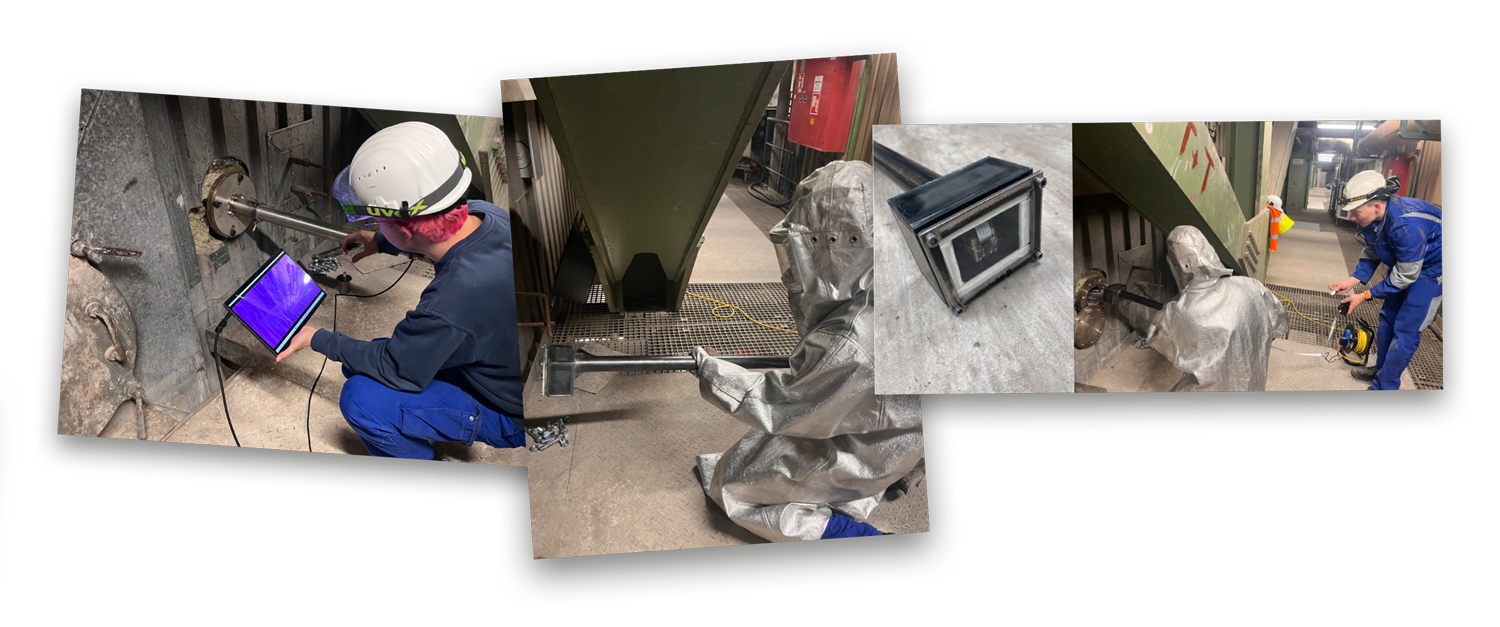

Monitoring the boiler system’s superheater

The second project has involved developing a superheater camera. The goal here is for this camera to create a time lapse video that can be called up via the operating database. By doing so, the camera can monitor the degree of soiling in the superheater’s pipes in the boiler. These components are particularly prone to corrosion and abrasion and deposits have a major impact on the flow of the flue gas. This, in turn, has a negative impact on boiler efficiency. Monitoring this makes it possible to alter maintenance cycles and gives a comprehensive picture of how corrosion and deposits build up inside the boiler, in particular in conjunction with other projects. This project has led to the group collaborating with the firm CheMin, which has developed a suitable camera. CheMin is, therefore, just as interested in the results of the tests as the IN GMVA team.

The idea originated within the team – and its implementation is a joint effort: thanks to cooperation with CheMin, a company that developed a suitable camera, the project ‘Monitoring superheaters in the boiler system’ is now becoming a reality. This is a great example of how internal curiosity and external partnerships can provide innovative impetus for our industry.

To keep up to date with modern working practices, the team members have also been collaborating with Startplatz, a start-up network, so that they can take part in intensive AI-related further training courses. By doing so, the Innovation Network members are given the opportunity to test highly innovative technologies, such as AI and robotics, and deal with the challenges associated with such technologies at an early stage. These projects deliver valuables ideas and impulses that enable such innovations to be integrated into other areas as well. Collaborating with start-ups plays a key role here.

Image credits: © GMVA