A highly unusual situation in Ilbesheim

Listed timber-framed buildings, well-known winegrowers and picturesque vineyards: Ilbesheim, a winemaking village in the Landau-Land district with 1,200 inhabitants, is a haven of tranquillity. At least, it normally is. Places like Ilbesheim, however, can also suddenly find themselves facing exceptional circumstances that demand a rapid response, the highest of safety standards and even an evacuation.

The way it began was quite unspectacular. A former vineyard in the centre of the village was sold and the new owner wanted to tidy the place up. He discovered a 20l metal drum in one of the sheds that did not look right. Not only was it rusty but also – and more worryingly – the drum had leaked some of its contents, a yellow powder, and had a warning label that was still legible. The new owner reported this to the police, who involved the fire brigade, the public order office and the district’s hazardous materials team.

As explosive as TNT

It became clear in no time at all that the situation needed to be handled very carefully. The decades-old drum contained a pesticide that has been banned in Germany since 1960 and is not only toxic but also highly explosive when it crystallises. In the state it was in, the drum had an estimated explosive force of around 10 kilograms of TNT. Enough to cause major damage – even to solid steel structures – within a radius of 100 metres.

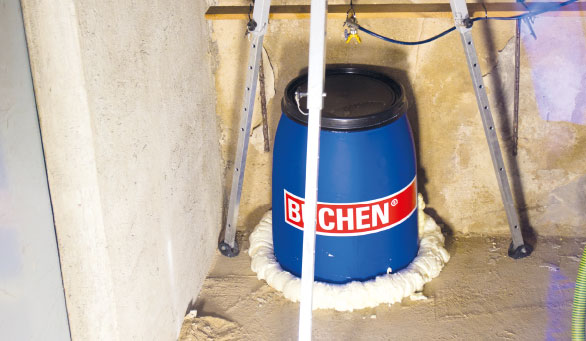

Which meant the village’s tranquillity was disturbed for a while. The drum had to be made safe as quickly and as securely as possible – and this had to be done by specialists. A call was put through to BUCHEN UmweltService who set everything that had to be done in motion. BUCHEN’s experts first had to plan the work meticulously. Taking all the potential risks and specific circumstances into account, they drew up a concept to remove and dispose of the drum. At the centre of their plan: an alkaline solution and a special epoxy resin that did not generate heat. At the same time, BUCHEN applied for all necessary permits, transported the equipment they needed to the vineyard and prepared the space to meet the requirements for performing work in a contaminated area.

An extensive range of safety equipment, including a 4-chamber, double-door system, had to be installed so the toxic drum could be removed

Salvage work in slow motion

They were ready to move in and remove the drum in July. First, 225 Ilbesheim residents had to leave their homes. The control centre was then set up and 80 specialist rescue operatives brought in to lend a hand if needed.

Supported by their team leader, two BUCHEN employees entered the shed to make the drum safe – experienced, safety-conscious operatives, who carry out such tasks as part of their everyday job. Wearing respiratory protective equipment and hazmat suits, they set up a sprinkler system and sprayed the drum with the lye, which immediately halted the risk of explosion. Calmly and with a level head, the well-practised team covered the whole of the rusty drum in a protective film to prevent it falling apart. As if in slow motion, the drum was then lifted up with a hoist and very carefully placed in a 120l salvage drum. The staff then filled this salvage drum with binding agents before pouring the epoxy resin into it, a step that had been approved by the Ministry of the Environment in Mainz.

The setting resin firmly joined the two drums together so that it was impossible for the toxic pesticide to escape. The job was successfully completed within around four hours. And the Ilbesheim residents could breathe easy again. The people who had been evacuated were able to return to their houses earlier than expected. The village was safe once again.

Staying safe in critical environments

Jobs such as the one in Ilbesheim really underline the strength of BUCHEN’s ‘safety first’ prerequisite. All areas of the Group are certified in accordance with exacting quality, safety and environmental standards. The employees also benefit from the advantages created by this system. Besides taking part in training courses and performing such tasks regularly, BUCHEN’s operatives can rest assured that all individual steps of a project have been carefully thought through and all safety aspects taken into account. Additional protection is provided by detailed risk assessments, project-related safety instructions and, last but by no means least, the company’s own workshops that ensure that all equipment and protective gear are always kept in an excellent condition.

Image credits: image 1: Adobe Stock: Rolf Ge.; image 2–3: © REMONDIS