Thermal treatment is not the best solution

Every day, millions of disposal nappies end up in the residual waste bin in Germany alone. Which means they end up at an incineration plant. This is, of course, anything but sustainable: while thermal treatment does indeed generate energy, it also means many other substances are lost to us forever. The Netherlands’ latest national waste management plan has taken a closer look at this waste stream to see how it might be recycled. As a result, many Dutch district authorities have already introduced a separate collection scheme for disposable nappies. So far, however, this step has proven to be unsuccessful as the country has not had access to a viable recycling plant able to offer a sustainable, low-carbon nappy recycling process.

Melting the nappies down rather than incinerating them

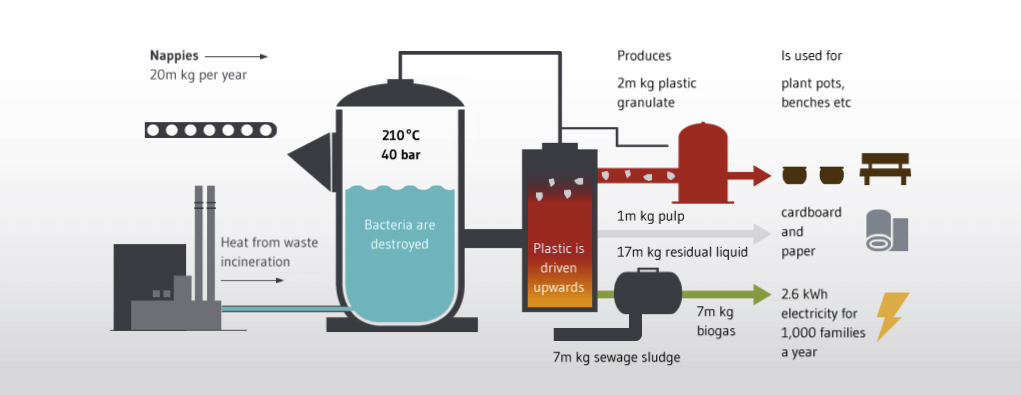

REMONDIS Niederlande is now leading the way across the whole of Europe by operating a nappy recycling system in the Dutch city of Nimwegen. This system was developed at the University of Brandenburg and is based on thermal pressure hydrolysis. During the process, which involves temperatures of 225°C and a pressure of 44 bar, the nappies are melted down as well as incinerated. Consequently, the individual components of the highly complex nappy product – primarily polymers and cellulose – can be separated from each other and recovered.

So what happens during the nappy recycling process?

“At the end of this process, we have recovered high quality recycled raw materials – in the form of plastic granules and paper – that we can then return to production cycles. Any leftover material undergoes a further treatment process where it is enriched with digested sewage sludge to produce high-purity biogas,” explained Dr Gerd Terbeck, managing director of REMONDIS Niederlande. A small pilot plant had been commissioned back in 2013 to test this system. A deliberate decision was made at the time to start small so that the technology could be gradually optimised over a long test period to get it ready for market. This latest plant, which has been in operation since the beginning of the year, will be able to process 15,000 tonnes of disposable nappies once it reaches full capacity. The local communities will benefit from the plant’s output materials: the recovered plastics can be used to make new products, such as plant pots, and the biogas from the Nimwegen plant can supply up to 1,000 homes with electricity. The paper will be used by paper mills to make new paper and cardboard. “Not only the raw materials, which are recovered and returned to production cycles, help to protect the environment and curb climate change. The actual recycling process itself is environmentally friendly as well. It helps reduce greenhouse gases – our plant will cut carbon emissions by 7.2 million kilogrammes every year,” said Dr Terbeck.

REMONDIS Niederlande – a trailblazer

REMONDIS’ goal is to continue to extend its nappy recycling capacities in order to further promote sustainable development. This is especially important as disposable nappies tend to be the product of choice of most parents of young children and this situation is unlikely to change.

The plant in Nimwegen cuts carbon emissions by 7.2 million kilogrammes every year.

To be able to achieve this goal, the company is already planning to build further plants in the Netherlands. Over the medium term, this process shall, of course, be set up in other European countries. If there is to be a successful disposable nappy recycling system in Germany, for example, then nappies must be kept apart from other waste streams and a separate collection scheme must be introduced across the country. Some European countries have begun setting up such systems but this is not true for the whole of Europe. REMONDIS, however, is setting a good example here by offering institutes, such as hospitals and care homes, waste management concepts that include a separate storage and collection system for absorbent hygiene products. Besides opening this new nappy recycling plant, REMONDIS Niederlande has also installed an innovative digester plant in Weurt and a district heat network and is actively looking into ways of effectively recycling orange peel.

Image credits: image 1: Adobe Stock: famveldman; image 2: iStock: emwar