China is making its position clear

China has a clear strategy when it comes to raw materials. It is not just the fact that the country has been on a shopping spree for years in the newly industrialising and developing countries of Africa in order to secure direct access to raw material reserves there. Last year the Middle Kingdom announced that it was investing an incredible 900 million dollars for the construction of a new Silk Road.

Already today, one branch of this modernised and as a result resurrected trade route ends in the freight rail station in Duisburg. The countries bordering on the new Silk Road are rejoicing over unexpected growth prospects. But it is also evident that the Silk Road is no one-way street. China is sending us its finished products and over the long or short run will be intent on bringing back supplies of raw materials to China. Neither the EU nor the USA have had any comparable strategy regarding raw materials thus far. There was considerable initial confusion, then, when the Chinese Ministry of Environment notified the World Trade Organisation on 18 July 2017 in letter WTO 17-3880 that it would be imposing a ban on imports of 24 types of waste to commence at the beginning of 2018.

A long list of unwanted materials

Plastic waste and ground plastic material, unsorted waste paper with more than 0.5% impurities, metallic slag and ash, textiles and even electronic waste and PET bottles were placed on the list of undesirable materials. At a more abstract level, the question arose as to whether the Chinese dragon was sated or simply interested in better food, i.e. pure-grade raw materials. Whatever the case may be, with this unprecedented move China has ratcheted up the political and economic pressure on Europe and other parts of the world to take action. But every crisis also harbours an opportunity. If the right steps are taken now, the crisis gripping the sale of plastic waste and other material can turn into a real boon for development of the European recycling industry.

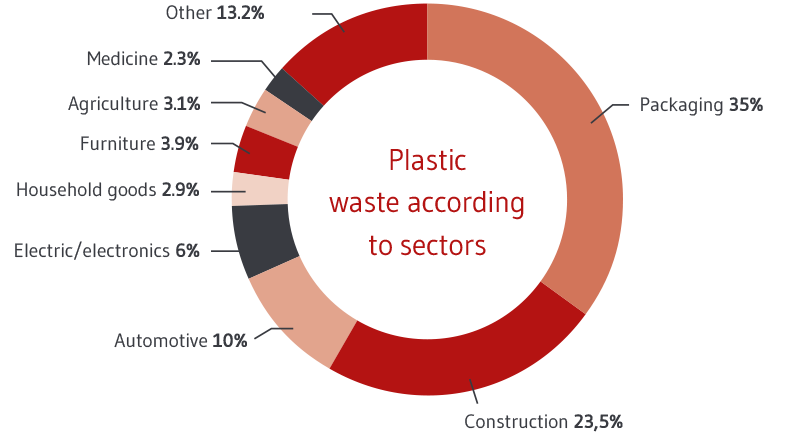

Particular focus on exports of mixed plastics

Germany has been exporting up to 750,000 tonnes of plastic waste every year to China, somewhat less than half of the total amount of material to be recycled that accrues in this country. By the same token, the quantities that are already pre-sorted by households from the “yellow bags“ and “yellow bins“ of the Dual System pose the least problem. Separating packaging material that has already been effectively pre-sorted using machines already at present produces virtually pure material flows, which German and European industry readily accept as raw materials. Primarily mixed plastics were exported in the form of ground material, finished granulate as raw material, which is produced in Germany from waste, PET bottles as pure raw material for the Chinese textile industry, foils and other plastics collected from commercial waste.

The rate of materials recycling in Europe is to be increased

Thermal utilisation, which is still excessive, is to be significantly decreased under the new packaging law. At the same time, the material recovery rate applying at present, 36 per cent of plastic waste, is to be raised to 63 per cent by 2022. Parallel to this, the European Union is working on a new package for the closed-loop economy with the aim of significantly boosting material recycling quotas in the Member States. With regard to commercial waste as well, the new Commercial Waste Ordinance is having an increasing impact, forcing companies to keep waste separately for the purpose of achieving higher levels of raw-material recovery.

The demand for recycled raw materials needs to rise

In this hopeful context, China has now imposed a ban on imports, striking one something like a rampaging “bull in a China shop“. The economy is booming, even exacerbating the problem, as more consumption also means more plastic waste. If China now accepts less plastic waste, this raises the question of where all the waste is to go to. The solution can only be to strengthen German and European recycling efforts in order to keep cleanly processed raw materials in a closed-loop production cycle. But for this to happen, there also need to be better incentives for customers, as the best raw materials are of no use if nobody buys them. Even German industry – which after all leads the world in the use of recycled material – only meets 14 per cent of its raw material requirements with recycling at present. Not bad, but there is considerable room for improvement. To turn China‘s ban on imports into a win-win situation both for industry and the recycling economy, a concerted compendium of measures is required, with three essential thrusts.

The triad of the future: new specifications of an ecodesign, a high level of sorting quality, a system of economic incentives for recyclate

What must be done in order to equally satisfy the needs of the environment, consumers and industry? There are already good ideas and well-intended policy strategies. They only need to be resolutely extended, expanded and supported politically with clever incentives in order to turn the crisis into an opportunity along the lines of a three-sided win-win situation.

It is with this in mind that REMONDIS is banking on a three-pronged initiative with the objective of forging a closed circle out of the linear approach characterising this field of business to date. The first prong targets product design:

1. New specifications for ecodesign directives

Present-day Ecodesign directives are largely limited to the energy efficiency of products. Household appliances and other consumer products are merely measured in terms of their energy efficiency and degree of utilisation. On top of this, aspects like emission limits, usability and requirements applying to product information for consumers are also taken into account. What has not played any role thus far is raw material efficiency.

Individual initiatives are no longer enough. Concerted action involving policy-makers, the recycling industry and manufacturing is needed now.

To point the recycling economy in the right direction for the future, an ecodesign directive should therefore be expanded to include the aspect of raw material efficiency. In other words: All products have to be conceived already in the development and design phase so that at the end of the product life cycle as close to 100 per cent as possible of all of the raw material contained in it can be recovered and recycled.

To offer maximum transparency to consumers, the enclosed or printed product information should contain a recycling efficiency label in the future, analogous to the established colour bar diagram for energy efficiency. This allows one to quickly recognise how easily a product can be recycled and what percentage of the product is made out of raw materials that have already been recycled.

In 2015, almost 99% of all plastic waste collected was recovered.

2. More investment in better sorting and recovery quality as well as research & development

REMONDIS is leading the way here once again and already now investing in new sorting and recycling plant and equipment, for example at Europe‘s largest centre for industrial recycling, Lippewerk in Lünen, where in addition to a new compost plant with biogas production there are also extruder lines for the granulation of plastic as well as for foil production from recycled foils in 2018. At the same time, REMONDIS is building one of its biggest and most efficient sorting facilities for recyclable material from the Dual System in Erfstadt, a suburb of Cologne.

Generally speaking, Germany and Europe have to invest more in optimal sorting and recycling in order to boost the quantity and quality of recovered raw materials. Only in this manner can recycled raw materials become an attractive alternative both in terms of price and quality for manufacturing while at the same time reducing pressure on the procurement of material.

The plastic industry and recycling experts largely agree, however, that existing processes alone will not suffice over the long haul. It is with this in mind that REMONDIS is banking on inter-industry cooperation in the development of new processes, above all in the area of plastic recycling, as the range of applications for the original raw material, naphtha or methane, is reduced significantly with each recycling process due to specific material properties. The silver bullet would for this reason be to separate plastic waste into its basic building blocks once again.

A solution: chemical recycling

With so-called chemical recycling, all suitable plastic waste is broken down into reusable polymers, monomers or premium-grade fuels by means of a chemical process. At the same time, these are pure, primary-grade raw materials without any impurities or rejected material whatsoever. To do this, plastic waste has to be separated from residual waste and foreign substances and cleaned before being sorted into the respective type of plastic. In the ensuing transformation into powder form by means of cryomilling, the material is reduced to grain sizes ranging from several hundredths to a few tens of millimetres.

Chemical recycling of plastics has the potential to solve some our most pressing environmental problems over the long term.

In the further course of the procedure, there are various technical options. At present, experts consider catalytic cracking to be the most promising method for chemical recycling in economic and ecological terms, however. Here, a suitable catalyser is used at moderate temperatures to produce a relatively narrow spectrum of hydrocarbons with relatively short chains. It is relatively easy to synthesise this raw material into a large number of new plastics. Nevertheless, research and development still face several challenges, for example with regard to suitable catalyst materials.

Volatile raw material markets, requirements in connection with protection of the oceans and climate as well as increasingly scarce resources are making plastic waste an ever more important source of raw material. Expensive mechanical recycling with all its quality problems is at the same time running up against its limits. Over the medium term, chemical recycling will become the predominant form of recycling; REMONDIS is already actively involved in research and development of this technology at present.

3. System of incentives for industry

The best recycling material can only fulfil its purpose if there is a need for it in the market. At present, German industry merely covers 14 per cent of its needs for raw materials from recycling, most of it from metal scrap. There is thus considerable room for expansion here. REMONDIS is calling on policy-makers to launch a system of incentives to foster the use of significantly more recyclate in manufacturing. In addition to the ecological and social superiority of recycled materials, there are many reasons favouring this alternative. The use of more high-quality recyclate from the raw material source of domestic waste means less pressure on procurement and less dependency on volatile international raw material markets.

This will not succeed without economic incentives for industry. Recycling materials must be promoted in a targeted manner.

It remains the task of policy-makers to select specific steering and control instruments. Whatever course is set at the political level, one side-effect will be a strengthening of the European waste and recycling economy through efforts to promote recycling of raw materials. Already at present, this sector accounts for a quarter of a million jobs in Germany and is one of its biggest engines of growth. Ideally, raw materials would remain in Europe in the future and be kept in a continuous closed-loop cycle in primary quality. Human beings, the environment, the oceans, climate and the economy would all profit equally. In such a highly desirable trajectory, the public sector plays a key role. It has to lead the way in the areas of procurement and subsidies and assign preference to and foster the use of recycled raw materials.

Image credits: image 1: Adobe Stock: Sergey, image 2: © REMONDIS