It truly is a very impressive size: distributed across three spacious production halls and covering a total 11,000m2, this innovative set-up will be transforming 180,000 tonnes of household and commercial waste into refuse derived fuel (RDF) every year as well as recovering any metals and removing the water content. GWA RE’s new processing facility will be operating a combination of technological solutions that has never been used in Germany before. Trial operations have begun on the facility, which is located on the grounds of the Lippe Plant in Lünen. It is expected to be up and running properly during the second half of 2023. All in all, a significant eight-figure sum has been invested in this project.

Looking at the waste hierarchy set out in German law, things are both clear and straightforward. Waste that can’t be avoided must be reused. What can’t be reused must, at the very minimum, be recycled. If this isn’t possible then the next stage is incineration and finally, at the very bottom of the hierarchy, disposal/landfilling. Which is right and so simple. The reality, however, is more complex: according to the latest figures published by the UBA [Federal Environment Agency], just 23.6% of the contents thrown into the grey (general waste) bin in 2020 actually belonged in the bin. For a start, this meant that almost 40% of organic waste and over 27% of recyclable materials were not put in the right bin and were unable to be recycled. Instead, they ended up, for the most part, at waste-to-energy (WtE) plants where fuels must still be added to ensure the incineration process remains clean.

Germany’s households and commercial businesses are, therefore, presenting the waste management sector with a complicated mixture of materials that is not as easy to handle as set out in the waste hierarchy. Separating all these materials again makes no sense – either from an environmental or an economic point of view. There are, though, technical ways to upcycle this waste.

And this is precisely the reason why GWA RE, a joint venture between the public sector business GWA (owned by the District of Unna) and REMONDIS, has now built Germany’s largest recyclables processing plant in Lünen. Currently in the process of being commissioned, this plant will primarily be producing RDF for power stations and cement works as well as recovering and recycling metals so they can be returned to market.

The plant

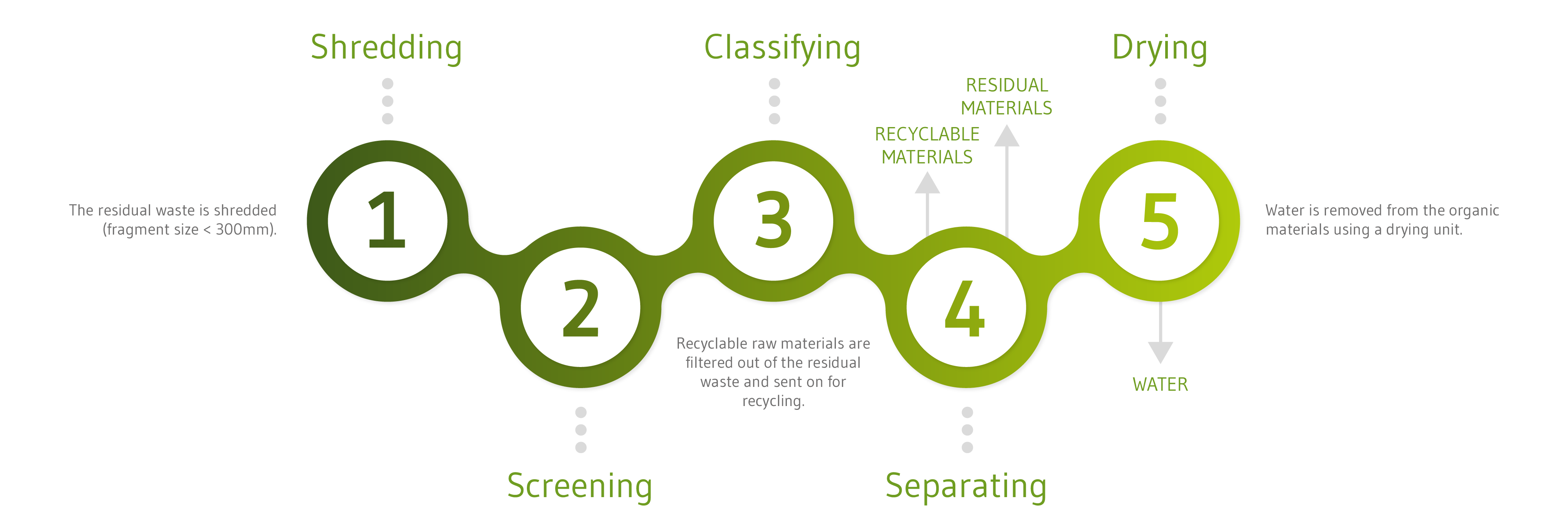

The plant’s size and its capacity to handle 180,000 tonnes a year is one of a kind in Germany. Plans are for it to process 100,000 tonnes of commercial waste, 70,000 tonnes of household and bulky waste as well as around 10,000 tonnes of other kinds of waste every year. The materials are sorted in the three production halls, covering over 11,000m², at the Lippe Plant. The first step of the process is to pre-shred the materials so that they can be sorted. They then undergo a series of steps which enable, for example, materials such as iron and aluminium to be separated and removed. At the same time, the process heat and air supply dries the waste stream out – almost incidentally. At the end of this stage, the materials are shredded once again. This step produces small shreds of material that are no bigger than a maximum 30mm. This product, known as fluff, can then be used as RDF by power stations and cement works instead of fossil fuel. And, with the energy prices being so high, fluff is an attractive product.

The first trials have shown that the plant is able to meet the planned performance parameters without any problems. It can process up to 70 tonnes of general household waste an hour and around 40 tonnes of commercial waste an hour. Patrick Wicker, managing director of GWA REsource Kreis Unna, commented: “So far the output of RDF produced has been above expectations. What’s also clear, though, is that a project of this size has thrown up some technical challenges – challenges that we’ve managed to master thanks to the hard work and good ideas of our staff. These experiences will definitely be useful when we operate the plant in the future.”

There are two particular features to this plant that effectively turn it into a role model: on the one hand, this is the first facility in Germany to use six near-infrared (NIR) scanners to process commercial waste and, on the other, it is the first to use such waste to produce high quality RDF. Comparable facilities are unable to achieve this at the moment as commercial waste has a lower calorific value than mixed plastic fractions and left-overs from sorting processes. Thanks to this innovative process, this new facility is now able to transform commercial waste into RDF for cement works for the very first time.

“In these times of scarce energy supplies, we are convinced that we’re making an important contribution towards conserving our planet’s natural resources.”

Patrick Wicker, Managing Director of GWA REsource Kreis Unna

Environmental footprint

Patrick Wicker describes the contribution that the facility makes towards curbing climate change and towards recycling as follows: “In these times of scarce energy supplies, we are convinced that we’re making an important contribution towards conserving our planet’s natural resources. This type of processing is – looking beyond the waste hierarchy – more valuable than incinerating waste at a WtE plant. What’s more, we also recover around 4% metals and up to 10% water from the materials. This means that the water doesn’t have to be transported and doesn’t worsen the energy footprint of incineration plants.”

A positive project all round then. Just a last look back at the waste hierarchy though: even if a technical solution has been found that is spearheading the way, this is still a costly and complex means to make up for what should really be done at households and commercial businesses. Something that is quite simple for them to do – namely to sort their waste properly, which is still the best solution no matter how innovative this facility is.

The technology

1. Pre-sorter excavator

2. A pre-shredder

an M&J 6000, two 250kW motors; these operate 2 rotor shafts, each with 14 rotating blades

3. Two flat filters

4. Two air separators

5. Three aluminium and three iron separators

6. Six NIR scanners

four 2.8 metres wide; two 2 metres wide

7. Sorting cubicle

plans are to use this during the start-up phase only and possibly in the future if the facility is expanded

8. Two secondary shredders

Lindner Komet 2800 HP, each with two belt drives (2x 250kW); the rotor is 2.8m long with a knife and a rotation rate of 367 revolutions per minute