The region between the Rhine and Ruhr is undergoing change. Mining and steel have been replaced by new worlds of work. In many places, however, well-preserved treasures of the past can still be seen. This makes it all the more important to preserve these industrial monuments for the long term. This is a task that XERVON actively supports – for example at the listed winding tower of the Deutsche Bergbau-Museum Bochum. We have already reported on the scaffolding work in this article. Now we provide an insight into the surface work and the work of additional trades.

„Refurbishing industrial monuments is one of our special areas of expertise. We reliably combine contemporary design with the special requirements of monument protection.“

Hendrik Stammler, Project Manager XERVON Surface Technology, Bottrop site

Well-known beyond the borders of Bochum

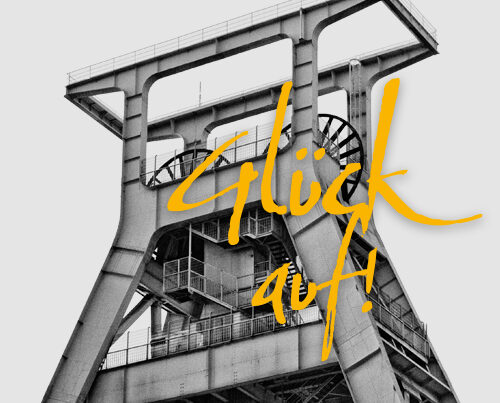

As one of the largest museums of its kind in the world, the Deutsches Bergbau-Museum Bochum – founded in 1930 – is dedicated to collecting, preserving, investigating, exhibiting and teaching the fascinating heritage of the mining industry. The largest exhibit is the 71 metre high winding tower. A steel giant painted in Germania green that is well-known far beyond the borders of Bochum. The headframe only came to Bochum from the former Germania colliery in Dortmund in 1973. Since then, however, it has characterised the city skyline and is a popular photo motif.

In order to make the steel monument fit for the coming years, a major refurbishment project with an ambitious schedule was launched last year. XERVON spent almost twelve months providing services in the key areas of surface technology, scaffolding and industrial services. A total of seven companies from the REMONDIS Group were involved in the renovation of the winding tower.

Corrosion protection follows scaffolding

In spring 2024, XERVON Gerüstbau set up scaffolding around the winding tower. The scaffolding, which comprised a total of 76,300 individual components, was then completely encased in a dust-tight housing surrounding the outside. The tarpaulin around the staircase-shaped enclosure covered 34 scaffolding levels – creating the work site for XERVON Oberflächentechnik. From April until early autumn, the specialists provided the winding tower with high-performance corrosion protection.

Taking all of the elements of the winding tower together, an area of around 10,000 square metres had to be refurbished. Around 10 tonnes of coating material and sealants were used.

In the first step, the surface experts used compressed air blasting to remove the existing old coating, including corrosion and adhesions. A total of around 500 tonnes of solid blasting media were used in this step. To avoid bringing too much weight to the site, the blasting material was transported essentially in a circuit: Compressors continuously conveyed the material upwards, where it was sucked out again directly during the blasting process, then fed downwards. The coating experts then sprayed the steel structure with a new, multi-layer coating system including a coloured top coat. Heating and air conditioning units installed in the work areas ensured that the required ambient conditions remained constant.

As space inside the enclosure was limited, most of the technical equipment had to be placed at the foot of the winding tower. In practice, this meant that blasting hoses, control cables and other supply lines had to be laid over long distances, sometimes up to 600 metres.

True team effort

Once all the work had been completed, XERVON Gerüstbau removed the 39,000 square metres of scaffolding on schedule. Despite the tight time frame and the large scale of the project, the restoration of the winding tower went according to plan. This success is also due to the fact that all services and companies involved worked closely together. If required, XERVON’s scaffolding and surface technology experts also involved additional trades from the entire REMONDIS Group. XERVON Instandhaltung in Bochum, for example, replaced severely damaged steel components in the winding tower. BUCHEN UmweltService ensured that the work areas were kept clean before the surface work began. The high-powered compressors used to transport compressed air were supplied by BUCHEN EnergyService. And REMONDIS companies such as REMEX, which specialises in mineral waste management, handled disposal of the blasting abrasives used.

The winding tower is one of the landmarks of the Ruhr area. Now that it has been renovated, it can continue to realise its full potential. Here’s to the next decades!

Image credits: © REMONDIS