A steel giant painted in Germania green: the headframe of Deutsches Bergbau-Museum Bochum, one of the region’s famous landmarks, is being renovated this year.

With three XERVON companies working together, the REMONDIS Maintenance & Services companies are responsible for the key scaffolding, surface technology and steel construction work. A total of seven REMONDIS Group companies are involved in the refurbishment of the headframe – a real team effort.

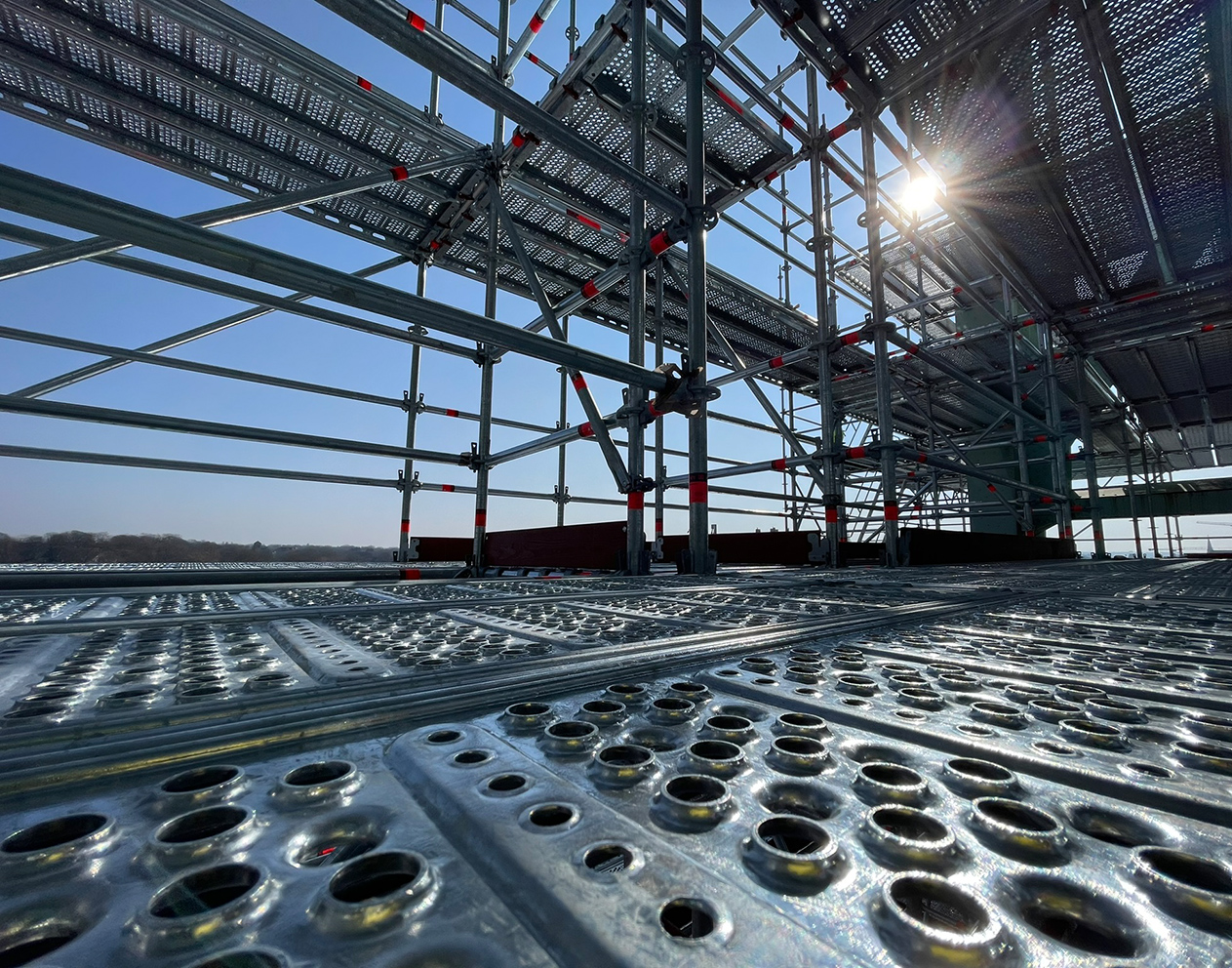

An ambitious plan has been put together to renovate this impressive steel structure: the work required to make the headframe fit for the next 25 years should take just twelve months. XERVON’s scaffolding experts, therefore, drew up a concept that involves meticulous planning, a tight schedule and clearly defined milestones. Always with the remit: speed and perfect organisation.

The listed headframe will remain in a 39,000 m3 scaffold until the end of the year for the renovation work

“From its historical background, to its unusual shape, to its impressive dimensions – scaffolding structures like this one are simply spectacular. It is an honour to be able to carry out such projects.”

Maurice Leese, XERVON Gerüstbau, Project Manager in Bottrop

Speed & perfect organisation in scaffolding

The team began erecting the scaffold at the beginning of February and, even at this stage, they had to take some special features into account. The headframe’s four supports are located in two of the Bergbau-Museum’s inner courtyards and converge at the top – and the tower has a 16-metre-high building under it. This meant for the scaffolders that the individual scaffolds around the lower section of the supports had to be erected so that the two scaffold structures were perfectly aligned when they met above the building. Precision was required here right down to the last millimetre, especially as a steel grid made of HEB beams had to be set up in one of the inner courtyards to bear the loads.

Read more about Deutsches Bergbau-Museum Bochum

Crane and elevator: customised logistics

The scaffold specialists also had to follow a strict logistics roadmap to ensure the huge volumes of material reached the site without a problem. As the museum did not have the space to store all of the material needed, it had to be delivered ‘just in time’. The routes taken by the lorries were planned to cause as little disturbance as possible for the visitors to the museum and local residents. XERVON’s team used a 160 t crane and a 1,500 kg elevator to lift the materials above the ground. Every hour counted to ensure they kept to the schedule.

As is the case with all projects, however, the team had to cope with some setbacks in Bochum as well. Strong winds, for example, meant that the scaffolders were unable to work for several days. Thanks to their dedication though, they were able to catch up and complete their task according to schedule. In the middle of April, they then handed over the 72-metre-high headframe, surrounded in enclosed scaffolding, to XERVON Oberflächentechnik’s team of surface technology specialists on time exactly as planned.

To be continued…

Watch the video [in German] for exciting insights into the work of XERVON’s scaffolding work!

But not only scaffolding and surface technology are being used. A total of seven companies from REMONDIS Group are involved in the renovation of the headframe. We will keep you updated about the process!

Image credits: © REMONDIS