At the same time, lithium-ion batteries are making up an ever greater proportion of discarded batteries. The danger of battery fires breaking out at recycling and waste management facilities is growing as more lithium-ion batteries are thrown into the wrong bin. As part of the UBA study ‘Assessment of the introduction of a mandatory deposit for single-use and rechargeable lithium batteries’, cyclos GmbH and Dr. Brüning Engineering UG looked at the different batteries to see where it would make sense to introduce a mandatory deposit – and where it would not. We recently met up with Dr Ralf Brüning and Mr Florian Piehl from Dr. Brüning Engineering UG to discuss this topic.

Dr Brüning, would a battery deposit be a suitable tool to reduce the risk of fires at recycling companies?

More and more fires are breaking out among e-waste, packaging, residual/bulky waste, mixed waste metals, paper and old textiles. A fire event occurs in waste collection bins and on refuse collection trucks – for example on the way to e-waste dismantling plants – in Germany practically every week. A deposit is, in principle, a suitable tool to help increase the number of single-use and rechargeable batteries collected, to ensure more lithium-ion batteries are separated from other materials at an earlier stage and to reduce fire events along the whole of the waste collection and treatment chain.

Having said that, a number of technical and organisational requirements have to be taken into account that will be needed as the number of lithium (high-energy) batteries coming onto the market grows.

What requirements would these be?

Organising and operating a comprehensive take-back scheme for batteries is an extremely complex undertaking. Batteries have to be labelled correctly and there needs to be a clearing house and a deposit settlement system to name just the most important requirements. On top of this, it’s not possible to charge a deposit retrospectively on batteries or battery-run products that have already been placed on the market.

It’s not possible, either from a practical or an organisational point of view, to introduce a ‘uniform’ deposit return scheme for all types of lithium-ion batteries – i.e. industrial, appliance and vehicle batteries – and for all battery designs at the moment, whether they are on their own or still inside a device.

Dr Ralf Brüning

Florian Piehl

So in which segment of the battery market would it make sense to charge a battery deposit to reduce the number of battery fires?

Introducing a deposit return scheme for the product groups ‘lithium batteries not installed in appliances (loose)’ and ‘appliances containing lithium batteries’ would likely have the greatest impact and so help reduce the fire risk. As far as the appliances containing batteries are concerned, then it would not only be necessary to set up a deposit return scheme but also to revise the statutory regulations in the German Act governing the Sale, Return and Environmentally Sound Disposal of Electrical and Electronic Equipment (ElektroG). This could, though, also create some synergies. Such a scheme could potentially increase the number of electrical devices collected as well as the number of old batteries.

Practically implementing such a deposit return scheme for both loose lithium batteries and devices containing lithium batteries would be complex. There are a number of tasks that could be particular challenging. These include setting up a system to enable the deposits to be charged when the products are placed on the market and getting the technology in place so the products can be returned. This, of course, must be both practicable and consumer-friendly. And then the batteries and the devices must be labelled to make it clear they are part of the deposit return scheme.

Deposit return schemes that are restricted to specific product groups (e.g. batteries installed in electric tools and ICT devices) would have a limited impact as the volumes in these sub-segments are comparatively low. What’s more, in such a scenario, it’s likely that large amounts of lithium-ion batteries would end up being thrown away incorrectly with other waste streams.

All in all, introducing a deposit on a selection of lithium-ion batteries is something that is seen as being conceivable – for example on ‘lithium batteries not installed in appliances (loose)’, on ‘electrical and electronic appliances containing lithium batteries’ and on industrial batteries used by households, in particular ‘batteries installed in e-bikes and e-scooters that can easily be removed by end users’. Setting up deposit return schemes in these

sub-segments could have a positive impact on achieving the intended goals – i.e. preventing batteries being discarded with other waste streams to reduce fire events and increasing the volumes of LIB and WEEE containing a LIB that are collected – and would be, to a certain extent, a suitable way to support the project goals.

“Improving the design of electrical and electronic devices, for example, could help make it easier for final consumers or the relevant service providers to simply swap out old lithium-ion batteries for new ones.”

Dr Ralf Brüning, Managing Director of Dr. Brüning Engineering UG

How much must the deposit be to ensure it has the desired effect?

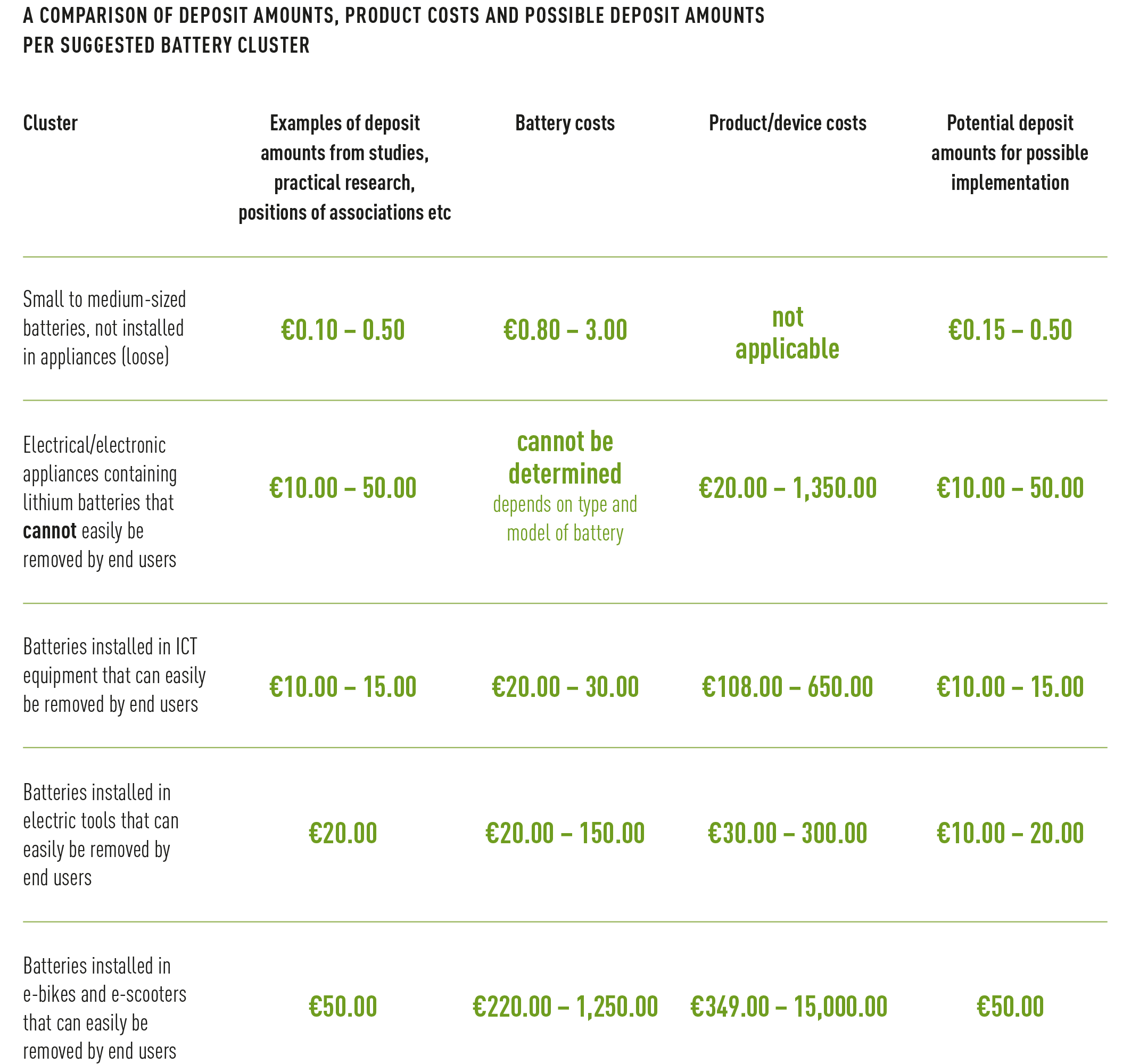

Potential deposit amounts are oriented towards the deposit amounts that had already been suggested during public discussions (editor’s note: see table) and are sums that are considered to be feasible in relation to the product costs. The potential deposit on small to medium-sized batteries found in devices covers a relevant proportion of the battery costs and is higher than the residual material value of the old battery. It can be assumed, therefore, that there would be a high return rate – similar to the deposit return scheme used for bottles. Another factor – alongside the deposit amount – that will play a decisive role on determining its impact is how easy it is for consumers to get to collection points and return such batteries and devices.

The reverse is true for all the other clusters containing the more expensive lithium-ion batteries. In such cases, the potential deposit amount is oriented towards what is an acceptable burden for the consumers in relation to the electrical and electronic equipment and the lithium-ion batteries installed in them. This means that the recommended deposit amounts are effectively an economic compromise that, it is assumed, consumers are, for the most part, able to bear.

Which lithium-ion batteries don’t need a deposit?

It was not considered necessary to introduce such a scheme for ‘traction batteries installed in electric and hybrid vehicles’, ‘traction batteries installed in other vehicles / industrial trucks’ and ‘energy storage systems’. Both the purchase and the disposal of such batteries are predetermined here because they are purchased or leased with the vehicle. If the battery is replaced, then this is almost always done by specialist garages or garages operated by the vehicle manufacturer or the seller. All this means that introducing a deposit return scheme for this cluster would not have a great impact on increasing collection rates.

In your opinion, what else can be done, besides battery deposits, to increase collection rates and minimise the risk of fires at recycling businesses?

There are many different measures that can help improve collection rates and minimise the fire risk. Improving the design of electrical and electronic devices, for example, could help make it easier for final consumers or the relevant service providers to simply swap out old lithium-ion batteries for new ones. The batteries themselves could be further developed to make them safer, for example by using non-flammable, thermally stable electrolytes and cathodes. The European Battery Directive could be revised in this area and define relevant minimum requirements. It would also be feasible to have a segregated collection scheme for waste electronic appliances that contain lithium-ion batteries.

Another important aspect here is raising awareness of this topic and making sure that all players along the whole of the waste management chain for batteries, e-waste and other waste streams know all about the risks. This includes, in particular, consumers, staff at collection and take-back points – e.g. shop employees – and the people working at waste sorting and treatment plants.

You can find the study (German) here

Source: German Environment Agency (UBA)

You can find more articles on batteries here:

Image credits: image 1: Shutterstock: DestinaDesign, Shutterstock: ValdekS, Shutterstock: paperbees; image 2, 3: © Dr. Brüning Engineering UG; image 4: Shutterstock: DestinaDesign