However, until this is possible – something that is hopefully not too far off – there will continue to be industrial production processes that generate residue that cannot be recycled. And it is these wastes that we should be handling more sustainably in the truest meaning of the word. Why? Because the two key factors here are safety and time. What is needed is a location that will not experience geological changes over the next hundreds of thousands of years so that nature safely encapsulates these residual materials. Here in Germany, this is only possible deep down in the ground in our old salt mines.

Working together, the circular economy and salt mines have proven to be ideal partners for delivering a sustainable, long-term and resource-friendly way of storing waste that cannot be recycled or used for energy recovery. Underground storage areas are the safest place for hazardous waste. These residual materials can be placed in the decommissioned sections of potash mines where they remain, gas-tight and watertight, separated from the biosphere by the layers of rock and salt which are hundreds of metres thick. This is the best place for them. There is no safer solution. These mined sections, up to 800 metres below ground, have the natural geological properties that provide the safest place for hazardous substances. Safely compacted here, all types of mineral wastes are laid to rest here for the final time.

Out of sight, out of mind? Absolutely not!

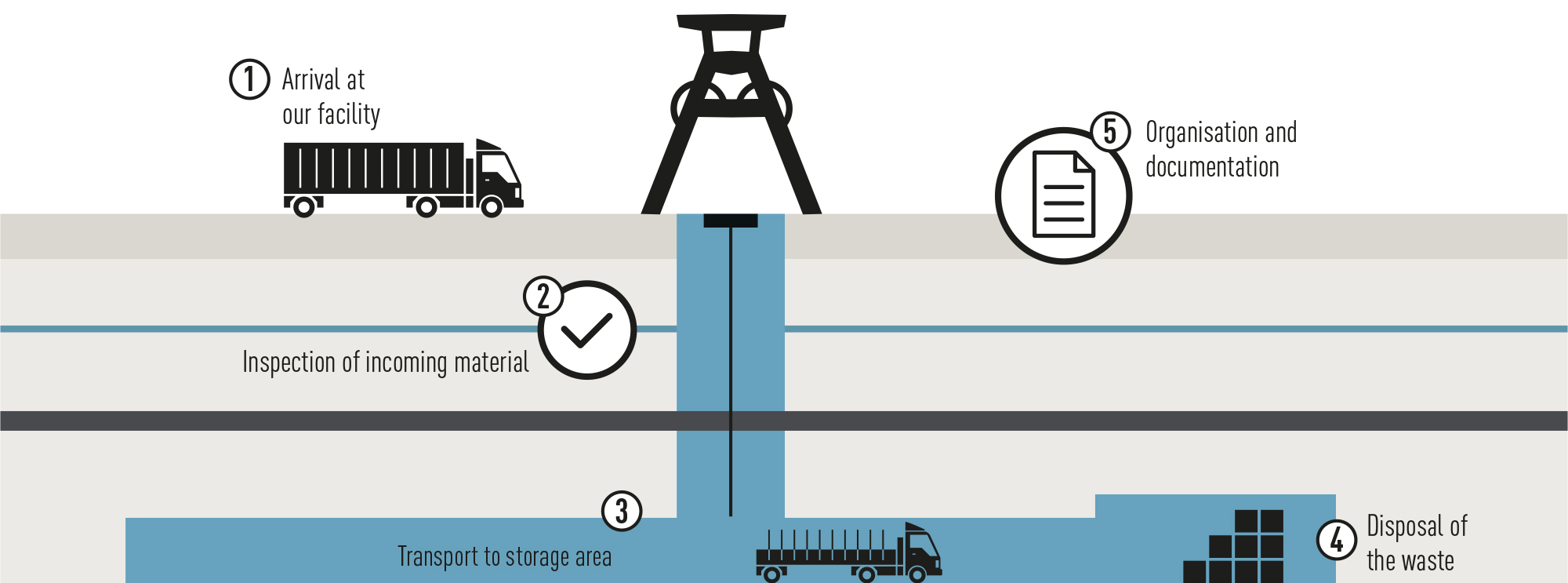

In line with the company’s stringent safety standards, all waste (1) that is delivered to our storage facilities – be it liquid, solid or dusty – is first checked. Besides ensuring that all papers and documentation are complete and correct, we also examine the packaging very carefully. A control sample is taken and stored before the waste is placed below ground. (2) The residual materials are then transported several hundred metres below the ground via a hoisting shaft. Special vehicles located under the ground then take the materials to their storage place which is often several kilometres from the shaft.

Different types of materials are stored in different areas for safety reasons. (3) Once it has reached its destination, the waste is stacked in storage chambers. A multi-barrier system is used to deposit the waste: when a storage chamber has been filled, it is sealed off with walls or salt barriers. (4) The volume and the nature of the waste, the area and the time it was deposited in are all documented. Furthermore, a control sample is stored in the sample archive below ground. It is, therefore, possible to see what substances are stored where at all times. (5)

50 years’ experience solving the challenges of tomorrow

The traditional mining company K+S and the mineral recycler REMEX have joined forces so that they can provide a wide range of industrial businesses and, in particular, waste-to-energy plants with a secure, long-term solution for their residual materials. Thanks to their newly founded company, REKS, they now have access to one of the largest underground storage capacities in the country.

They have over half a century of experience in their two underground storage facilities in Herfa-Neurode (in the German state of Hessen) and Zielitz (in the German state of Saxony-Anhalt). Herfa-Neurode was the world’s first ever underground storage facility with the first tonne of hazardous waste being deposited there back in 1972. A unique process has been developed over the years to provide a long-term and secure storage place for the waste in decommissioned sections of the mines as well as to stabilise the cavities with the deposited materials.

German law stipulates that sections of mines that are no longer used for extracting raw materials and that do not meet today’s safety standards must be backfilled. This also affects the mines in Zielitz and Herfa-Neurode. They meet their statutory backfilling obligations by depositing non-recyclable waste in the cavities created as a result of mining potash and rock salt. This conserves valuable virgin raw materials and makes an important contribution towards the disposal of hazardous residual materials.

The term “disposal”, however, is a word that is gradually being phased out at REKS. The only time this term should ever really be used is for hazardous waste that has no chance of being recycled. The REMEX and K+S joint venture is also proving that this is the case, especially above ground, where they create near-natural spaces and recover raw materials. By capping and sealing off potash waste heaps and recycling aluminium slag containing salt, they create new landscapes and sustainably conserve natural resources.

Some time, in the far-away future, the last thing that we humans “dispose of” will hopefully be the term “disposal”. And only the residual mineral materials safely deposited deep in the ground will remind us of a time when humans produced things that had a beginning and an end. The moment we have perfectly closed material cycles will signal the start of a long recovery period for our planet.

Image credits: image 1: REMONDIS; image 2: Adobe Stock: Blickfang