Working under the most difficult of conditions

Climatic conditions like in the Arctic, enormous distances and a large tank equipped with extra-long, particularly stable liner tubes: In this contract in Russia, BUCHEN is demonstrating that it is possible to perform professional work under the most adverse conditions.

An important transhipment centre

Far off in eastern Siberia, directly on the Sea of Japan, lies the Russian town of De-Kastri. Fewer than 4,000 live here, but the region is an important economic hub. The nearby export harbour is one of the biggest oil terminals in the Far East. The entire oil production of the Sachalin-I Consortium, one of Russia‘s biggest crude oil and natural gas exploitation projects, is transhipped at the site.

BUCHEN works with closed, automated cleaning systems that are in line with international market requirements.

The terminal has two large tanks measuring 100 meters in diameter respectively and a nominal volume of 112,000 cubic metres each. One of the two crude oil tanks had to recently be emptied for inspection and welding work that needed to be performed, in which residual sludge was to be removed and the tank carefully cleaned – a job for BUCHEN. After all, the company is also highly reputed in Russia for its professional large-tank-cleaning services in line with the most stringent standards – even under difficult conditions.

Crossing the country with the equipment

Challenges in the De-Kastri job especially relate to its isolated location. Ljudmila Ochotnikova, managing director of the Russian subsidiary BUCHEN Industrial Services OOO, headquartered in Ufa, comments as follows: “The vast expanses of the country require forward-looking supply logistics. If there are any breakdowns or bottlenecks, spare parts and additional human resources cannot be found right around the corner. One has to get used to that.“ This is precisely what the tank-cleaning professionals have done, transporting a reserve unit to De-Kastri to back up the first-line equipment. All in all, technical equipment ranged from the jet-washer system to nitrogen generators and pressurised pumps all the way to a repair workshop for dust masks. A distance of 7,600 kilometres lies between the head offices of the Russian BUCHEN subsidiary and the worksite.

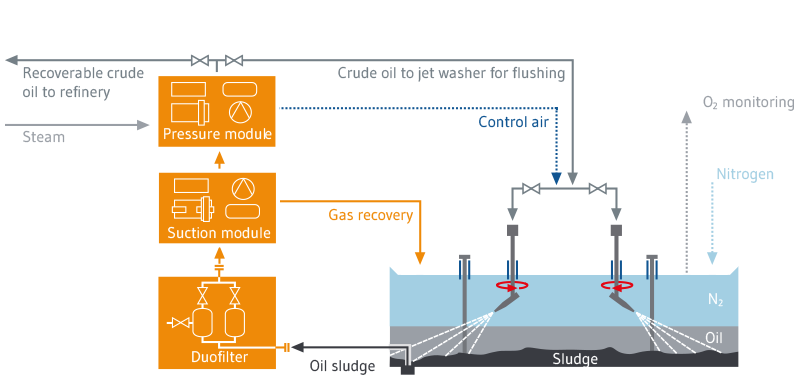

Diagram of the jet washer system

Different conditions, the same standards

Specific conditions in the country that BUCHEN is confronted with in its various jobs may differ, but with regard to occupational health and safety as well as environmental standards there are no differences. “Our processes, our methods, our know-how, technical and safety training for staff – all these things are just as important in Russia as they are in Europe,“ according to Ljudmila Ochotnikova.

When cleaning large tanks, BUCHEN uses jet washer systems that can be transported in an optimum manner thanks to their modular structure.

Regardless of the conditions under which BUCHEN works, the advantages for customers are the same everywhere in the world: thanks to realistic, reliable time scheduling, production can be resumed quickly. Di-Kastri as well will thus be able to recommence operations quickly, efficiently and successfully.

Special cutting unit: an individually tailored solution

The job in De-Kastri, lasting several months, was carefully planned and carefully prepared by BUCHEN specialists. This also involved the development of method standards, which specify all phases of work and the technology and equipment to be used in advance. This also required design and production of a special cutting unit for the pipes lining the tank roof supports. The unusually long, stable pipes had to be shortened in the course of the work in order to be able to bring the jet-washer system‘s flushing and rotation nozzles inside the tank. The workflow plan for the removal of the tank roof supports and the strategy for cutting the liner pipes were developed by BUCHEN in close collaboration with Exxon Neftegas, the operator of the facility. According to Ljudmila Ochotnikova: “The professional approach, our efficient cleaning process and the successful completion of the work on schedule showed that we were the right partner. We have been able to gain another reference project with De-Kastri.“

7,500 kilometres lie between the BUCHEN sites in Ufa and the jobsite in De-Kastri

Image credits: image 1: Fotolia: fotofabrika; image 2: © REMONDIS; image 3: Fotolia: cbies