Complex logistics covering route planning and vehicle and staff deployment

Most people have experienced it at some time or other: having gathered together enough bags of old bottles and paper at home, they then drag them to the nearest bottle bank or paper recycling bin only to find they are full to bursting. No amount of pushing will make space either. The last thing on a person’s mind when they are standing there with their full bags is just what a complex process it actually is to empty such bins. It takes a lot of work to plan the routes, vehicles and staff. REMONDIS Digital Services GmbH has now developed software to ensure drivers can plan their future routes efficiently and sustainably and that there are no wasted journeys. The name of the software: BINITY.

Bins equipped with sensors

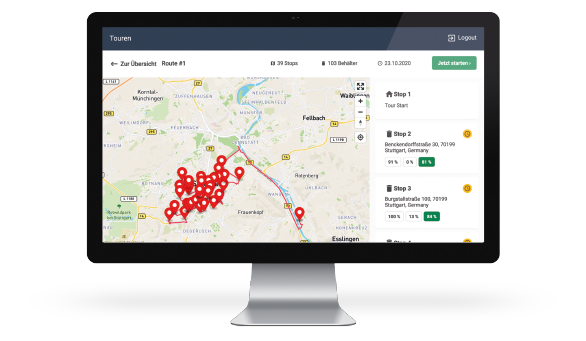

Some bottle banks and paper recycling bins are used so often that they are almost permanently overflowing. Others are visited so rarely that it makes no sense to empty them frequently. It is neither efficient nor sustainable for collection lorries to drive to empty bins. Time is lost and the flow of traffic is impacted. The software solution BINITY provides a digital overview of the situation – depicting all the bins, vehicles and routes. This enables the routes to be planned efficiently and makes the whole collection process more transparent. What’s more, the software makes it possible for new drivers to learn their jobs, for replacements to be found if a driver calls in sick and, if there is an unexpected interruption, for lorries to continue exactly where the work had stopped. All data is available at a glance – or rather with a single click. And BINITY can do even more: if a bottle bank is equipped with a sensor, the software can also measure the fill level.

All bins, vehicles and routes are depicted in BINITY. This provides schedulers with an overview when planning collection routes

A digital cockpit

The first thing that needs to be done is to digitise the collection operations, i.e. to feed the planned routes – which are normally handwritten or in Excel spreadsheets – into the system. The drivers can use a whole range of options once the data is in the ‘digital cockpit’. While carrying out their work, they can see which bins still need to be emptied, enter information about fill levels and add photos and comments. By doing so, they put more and more information into the digital database, all of which will help them to plan their future routes.

BINITY is already being deployed in the District of Heilbronn by the tin can collection team. In this particular case, one vehicle has one week to empty a total of 300 tin can recycling banks. “Our goal was to provide the scheduling department with a simple and useful IT tool to help them plan and optimise their collection routes,” explained branch manager Tobias Kutz. And it was well worth its while: thanks to BINITY, the time needed to empty the bins has been reduced from five days to four.

Thanks to BINITY, there are no wasted journeys. This saves time – time which can be put to good use for other tasks.

The live data is also very useful as customers often ring up to find out how many bins have already been emptied: “The office staff no longer need to contact the drivers as they mark the bins they have emptied on their tablet and are then guided to the next container.” Tobias Kutz is pleased with the system so far and emphasised: “One of the main reasons why we’ve been able to use the software so successfully can certainly be put down to the close collaboration with REMONDIS Innovation Hub.”

REMONDIS Innovation Hub’s goal is to turn ideas into marketable solutions. BINITY is the second product to be marketed by REMONDIS Digital Services.

Keeping an eye on fill levels

What works well in Heilbronn may be less suitable for other collection areas. Which is why BINITY can be adapted and extended to meet individual needs. The route-planning process can be static (without sensors), dynamic (full sensor system) or hybrid.

Bottle banks or recycling bins set up in remote or less frequented areas can often pose a challenge as it is difficult to know when they are full. When does it make sense to drive out and empty them? The dynamic or hybrid solution can help out here: every container (dynamic) or a selection of bins (hybrid) are fitted with a sensor that records the fill level. This information is then used to automatically determine the best collection route for a certain day. If the sensor shows a low fill level then there is no need for a lorry to travel to the bin. Likewise, this system prevents bins from getting too full.

For towns and for business premises

What can be used in cities can also be used on industrial grounds. Factory premises can be depicted in BINITY and the location of the bins added to the map. With the help of an app, the industrial customers can then let the waste management companies know when the bins need to be emptied. Sensors can also be fitted to the bins to keep an eye on fill levels and monitor the system by GPS. As a result, in-house waste management processes can be digitally monitored and optimised.

Thanks to BINITY, there are no wasted journeys. This saves time – time which can be put to good use for other tasks. What is even more important: the software helps curb climate change. Every unnecessary trip that can be avoided means fewer carbon emissions. So everyone benefits from this solution. The local inhabitants, who have efficient waste collections. The drivers, whose daily work is made easier. And our planet – which needs to be protected.

Image credits: image 1: Adobe Stock: studioworkstock; image 2: © REMONDIS