Access to this valuable raw material is limited

Water is not a resource that can be taken for granted in India. On the contrary, the volumes of water available to manufacturers are extremely limited. Which is why many are pinning their hopes on a new system that is currently being introduced: the so-called zero liquid discharge concept or ZLD that creates a wastewater-free production cycle. With REMONDIS Aqua offering this system to its customers, it is already proving to be a success in India.

The solution: a closed-cycle system

Many businesses in India have major problems accessing water in the dry months before the monsoon season – a problem that often leads to outages. A number of ideas have been suggested to improve water management in production plants and one in particular is spearheading the way: the ZLD system. This involves an independent, closed-loop water cycle that manages the use and treatment of the water so that it can be recycled on site at the plant. The ZLD solution enables the production water to be processed and recycled after it has been used so that it can once again be returned and reused as treated process water. Many industrial firms in India have helped ensure their business remains competitive over the long term by having the ZLD system installed at their plants.

REMONDIS Aqua is sharing its know-how

Being an expert in wastewater treatment and drinking water supply, REMONDIS Aqua realised early on that there was a need for ZLD in this region. It has already launched a comprehensive range of services related to this system over the last three years – and this despite the fact that ZLD technology is extremely complex both to design and run. REMONDIS Aqua is one of just a handful of companies with the necessary expertise and many Indian businesses and international firms based in India have already benefited from its knowledge. The company has now become one of the leading providers of ZLD technology applications. Besides helping to secure the future of industrial firms in India, the system also has a positive impact on the environment. Thomas Block, managing director of REMONDIS Aqua India Pvt. Ltd., explained: “The volume of raw water captured by the ZLD systems – so it can be reused as process and production water – helps stabilise the whole of the Indian water supply network.” What’s more, the installation of ZLD technology helps grow the local economy and strengthens REMONDIS’ position on the Indian market, he continued.

“The volume of raw water captured by the ZLD systems – so it can be reused as process and production water – helps stabilise the whole of the Indian water supply network.”

Thomas Block, Managing Director, REMONDIS Aqua India Pvt. Ltd.

Polyplastics project

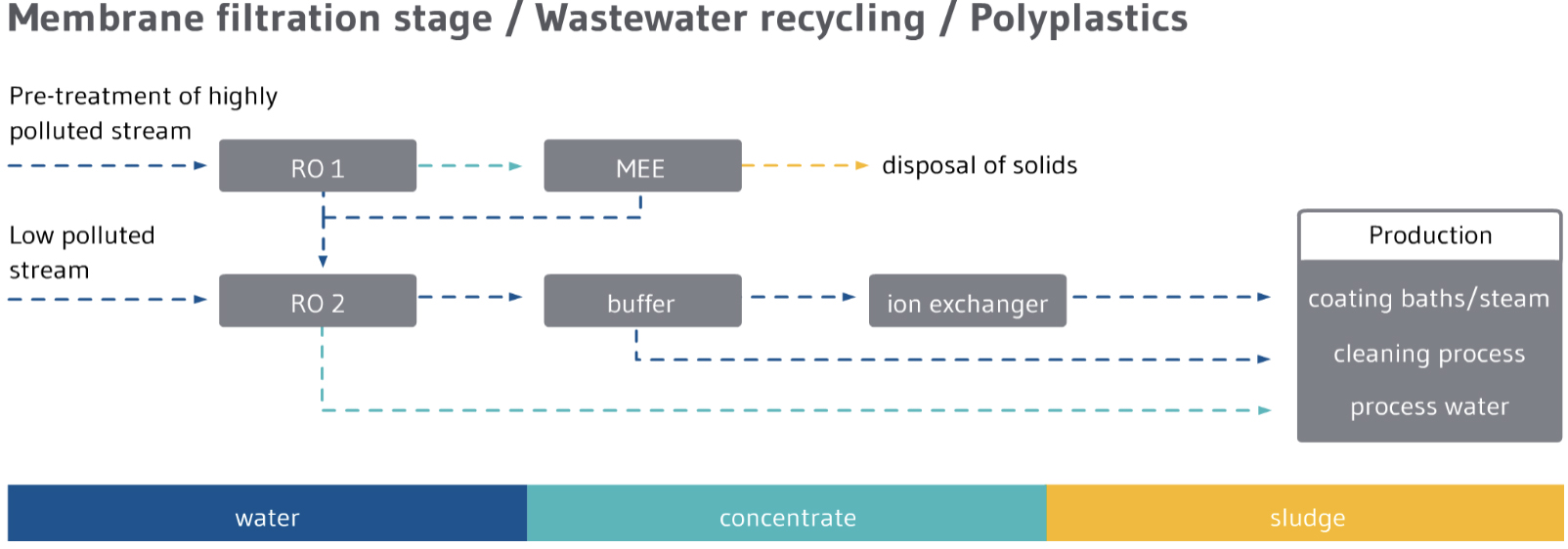

REMONDIS Aqua successfully realised its first ZLD project at Polyplastics’ plant in Bhiwadi in 2016. This firm, which manufactures plastic parts for the automobile industry, had REMONDIS plan, build, commission and run a ZLD system at the site. The technology has been up and running since 2017 and is able to recycle a total of 200m³ of wastewater generated by the surface treatment facility every day. The wastewater, which also contains heavy metals such as chromium, zinc and nickel, first undergoes a chemical-physical pre-treatment stage before being cleaned using ultra-filtration, reverse osmosis (RO) technology and sludge treatment. A further ZLD facility is currently being set up at Polyplastics’ new site in Viramgam, which is also being built – and will be run – by REMONDIS.

Evonik project

A ZLD facility is also in the process of being built for the chemicals company Evonik at its plant in Dombivli. Besides planning, building, commissioning and operating the facility, REMONDIS Aqua’s services for this particular project also include financing the ZLD system. All in all, this facility, which will be able to recycle around 600m³ of wastewater a day, will comprise a chemical-physical pre-treatment stage, ultra-filtration and reverse osmosis technology as well as a multi-effect evaporation (MEE) system.

Givaudan project

In 2018, REMONDIS built its first fully automated ZLD facility for the flavours and fragrances company Givaudan. This system has a throughput of 110m³ per day. Unlike the other facilities, the production wastewater undergoes a biological rather than a chemical pre-treatment phase. Following this, though, it is also recycled using ultra-filtration and reverse osmosis technology and a multi-effect evaporation system so it can be reused in the production process.

Image credits: image 1: iStock: Sudowoodo; image 2: © REMONDIS