A spectre is haunting Germany – the spectre of deindustrialisation. A few weeks ago, the five leading economic institutes wrote in their Autumn 2024 Joint Economic Forecast that the German economy will not grow in 2024 for a second year in a row. Gross domestic product is at pre-covid levels and the forecasts for the coming year are not much better either: both structural change and the economic slump will result in the German economy stagnating for the foreseeable future. There’s no doubt about it: the German economy is in deep crisis. But a crisis can also be an opportunity for renewal. The next German government – no matter what its party colours may be – will have to make a determined effort to carry on with this transition.

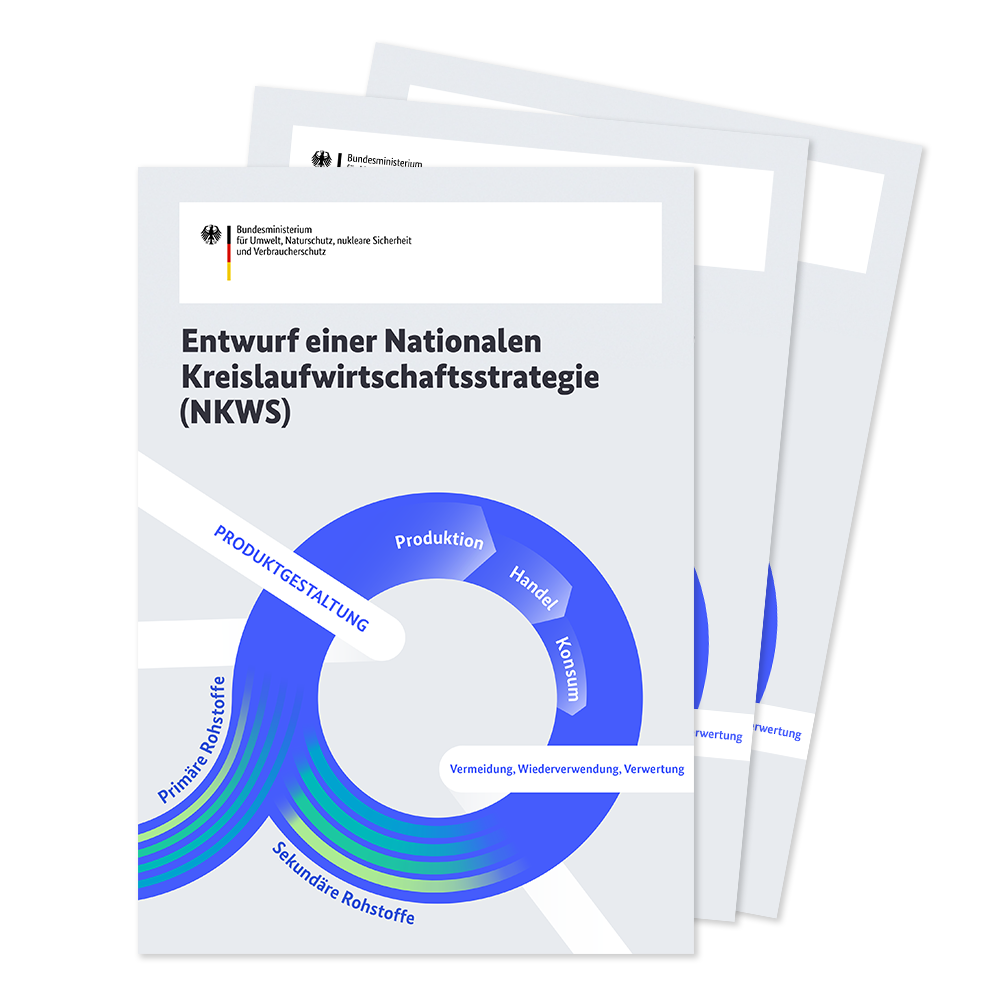

The circular economy can make a considerable contribution towards reviving the German economy. Whether it be recycling waste plastic, transforming construction waste into high-quality recycled aggregate, recovering valuable metals and raw materials from complex industrial products (such as e-waste and batteries) or producing climate-neutral biogas and fuels from biogenic waste and residual materials: Germany’s circular economy already has technological solutions that are in high demand all around the world.

The circular economy can make a considerable contribution towards reviving the German economy.

Exploiting the circular economy’s potential

However, neither Germany nor the EU are making the most of the potential that could be created by systematically implementing their circular economy. Just one example: experts estimate that the EU could potentially meet more than half to three quarters of its metal requirements for clean technologies in 2050 through local recycling. Globally, a systematically implemented circular economy has the potential to reduce global greenhouse gas emissions by just under 40% and consumption of raw materials by just under 30%.

This would have a particularly positive impact on Germany’s competitive position: a joint study published by the consultancy firm Deloitte and the BDI [Federation of German Industries] reveals that a circular economy could increase German industry’s gross value added (GVA) by 12 billion euros a year – something that would also have a positive net employment effect of around 180,000 additional jobs.

At the same time, dependency on imports of raw materials from countries like China would drop considerably. The study’s authors estimate that the use of secondary raw materials in the steel sector could increase from the current 44% to 58% by 2030 and in the aluminium sector from the current 53% to 72%. This would, in particular, help the German automobile industry to free itself – to a certain extent – from its dependency on raw materials from its now competitor the People’s Republic of China.

Having said this the circular economy must also further develop its own abilities. If it fails to do this, it will struggle to make much of a contribution towards the revival of the German economy. The German government made the first move when it passed its National Circular Economy Strategy at the beginning of December, and the next government – no matter what the coalition of parties may be – must implement this quickly. There is no doubt that global environmental problems caused by plastic pollution, the progression of climate change and the hunger of the world’s ever-growing population for natural resources will lead to a growth in demand for solutions all around the globe. Solutions put forward by the German economy will only be taken seriously if these best practices have been implemented in Germany itself and can actually be viewed by potential buyers.

Driving ‘circularity made in Germany’ with dynamism and compliance

For this to happen, German regulatory processes must become more flexible and less bureaucratic and the country’s laws and ordinances must be implemented more systematically. Having to wait years and years to get an approval to invest in Germany is unacceptable for a future market such as the circular economy – not only because of the unquestionable pressure that exists for everyone to act and help protect the environment but also because this excessive scepticism may result in Germany (once again) squandering economic opportunities. On the other hand, the fact that there are still regional councils in Germany that have not provided their households with food and garden waste bins even though this has been prescribed by the German Circular Economy Law [KrWG] since 2015 must not be allowed to continue without consequences. Consistently complying with the laws of the land must once again become one of Germany’s guiding principles – both for private and public sector actors.

If the circular economy is to be further developed and Germany is to set itself up across the world as a forerunner with the best solutions, then the concept of circularity as demonstrated by the traditional recycling sector must become even more firmly anchored in industry. ‘Circularity made in Germany’ – as the National Circular Economy Strategy rightly puts it – can then become a global export success. The best way to do this is through partnerships such as those that the REMONDIS Group has entered into, for example with Mercedes-Benz in the area of metal recycling and with the fashion chain H&M in the area of textiles. These need to be followed by cross-sector collaborations to close the life cycles of complex material streams as well as to develop solutions for the global market – something for which Germany and its partnership-based economy are effectively predestined. It is right, therefore, that the German government plans to set up a Circular Economy Platform to institutionalise stakeholder dialogue about the National Circular Economy Strategy.

Digitisation: turning material streams into data

For Germany to take on a leading role in implementing the circular economy, then it is essential that the country’s own circular economy uses digital solutions. Artificial intelligence can already help today to keep our streets and towns clean without the need for more manpower. Digital product passports will become a game changer in the circular economy in the future – not only because they will make recycling easier but also because they will translate real material streams into digital data. These new data sets will take both the appreciation for circular product design and the opportunities to recover raw materials to a completely new level. However, the global Circular Valley of the 21st Century – and the prosperity for everyone that this will bring with it – can only come into being here in Germany, if it is able to develop and offer suitable digital solutions alongside the right plant technology and business and organisational know-how.

In order to drive forward such digital innovations, the next German government must define the framework conditions for creating a new entrepreneurial and start-up culture within the circular economy. The dynamics of this start-up scene can and must be promoted by enabling and supporting real laboratories so that innovative ideas can be tested in specific spaces and environments. At the end of the day, not every idea will pass the practical tests. Some, however, will – and they will have the wherewithal to not only make the world a little bit more resource-friendly, cleaner and better but also to help Germany achieve new growth.

Image credits: image 1: Adobe Stock: Dee karen; image 2: Adobe Stock: wolcan